Mandatory asset inspection is crucial for utilities. Employees are often challenged with hard-to-access areas, heights or risky terrains. The traditional examination methods such as on-foot patrols, helicopters or industrial climbers are costly and time-consuming. Read more to learn how Axpo tackled these challenges by using the latest P3 Payload sensor technology from Phase One and LINIA’s drone software for automated power line inspection.

Ensuring Supply and Security

People rely on their nation’s power supply. They like knowing that when they flip a switch or need to charge our phone battery, the power is there to make it work the way that they expect it to. Delivering that power to each house involves several thousand kilometres of power lines that make up the backbone of the power supply. But with power lines, there is a risk of failure. For the power grid to keep supplying consistent power, companies must regularly check the power lines to ensure that there are no damaged areas that could cause failure in the future.

While these inspections were previously done manually by special visual inspection teams, this meant that employees were required to work at heights and in dangerous circumstances. In addition, manual inspection not only resulted in huge logistical efforts using cherry pickers and cranes and created work grounding and periods of going off grid, but it also posed a great risk of occupational hazards. Thankfully, one way to make power line inspections safer and more efficient is the use of unmanned aerial vehicles (UAVs or ‘drones’), high-resolution sensors and drone automation software.

Axpo – Providing Climate-friendly Power for Switzerland and Beyond

Together with its partners, Axpo operates more than a hundred power plants. The company’s climate-friendly Swiss electricity mix features reduced CO2 emissions and consists of hydropower, biomass, solar, wind and nuclear energy. Axpo is not only Switzerland’s largest producer of hydropower but also its largest producer of renewable energy, supplying customers with up to 3,200MW of capacity via a 2,200km distribution line (110, 50 and 16 kilovolts). Axpo has over 5,000 employees worldwide, over a hundred years of experience and operates in more than 30 countries.

Taking the Next Step for a Faster, Safer and More Efficient Inspection

Stretching 2,200km with 7,500 masts, the Axpo distribution lines require a significant effort to regularly inspect all parts of the vast grid to ensure stability. In addition to masts, isolators and rooftops, inspection tasks also include bird protection hoods, wires and screws.

Before purchasing the Phase One P3 Payload with the iXM100 sensor, Axpo used common drones with standard sensors for asset inspection. This was associated with several downsides, including time needed, unsafe distances to power lines and masts, and inadequate data quality.

To achieve a ground sampling distance (GSD) of 0.5mm/px, it was sometimes necessary to fly as little as three metres from the systems, which posed a substantial safety risk. In addition, six or more images were needed to be able to fully inspect the concrete poles. For much larger transmission system operator (TSO) systems, at least twice the number of images was needed for a full inspection, plus the greater safety distances required made it impossible to achieve the necessary GSD of 1.0mm/px.

How Phase One’s P3 Can Help to Streamline Effort and Improve Quality and Safety

With the Phase One solution, Axpo can easily tackle these challenges. Firstly, a maximum of just four images are needed to show the mast completely. Meanwhile, the high-resolution iXM 100MP camera provides a better and more detailed shot, while allowing the flight to be conducted at a greatly increased and much safer distance. Thanks to gaining distance without losing the information on the image (in fact, more information is likely to be available), Axpo is able to use standardized flight patterns and thus improve both productivity and quality.

The P3’s integrated laser rangefinder allows Axpo to exactly determine all distances and adjust them if necessary to ensure that the focus remains the same – even in the case of lattice masts, which have openings due to the lattice structure.

Thanks to the iXM 100MP, Axpo can now generate high-resolution and detailed photos with no loss of information when using the zoom function. These photos enable off-flight control and can also be viewed again at a later point in time, enabling full documentation of the condition and development of the grid over time and offering in-depth insights into operational data.

Another benefit of the P3 is that the service – flight and evaluation – can now be carried out completely in-house, without having to involve a third party, again adding to efficiency and cost savings. While handling large volumes of image data initially posed a challenge for Axpo, the company has since decided on new approaches for data storage, display and image processing, further streamlining the workflow and efficiency.

LINIAair Drone Application Enables a Fast, Structured and Reliable Data Acquisition Process

A drone pilot can easily capture data of a single power line tower. The challenge arises when a thousand or more towers need to be inspected in a short period of time. How can consistent, safe and well-structured data acquisition be ensured?

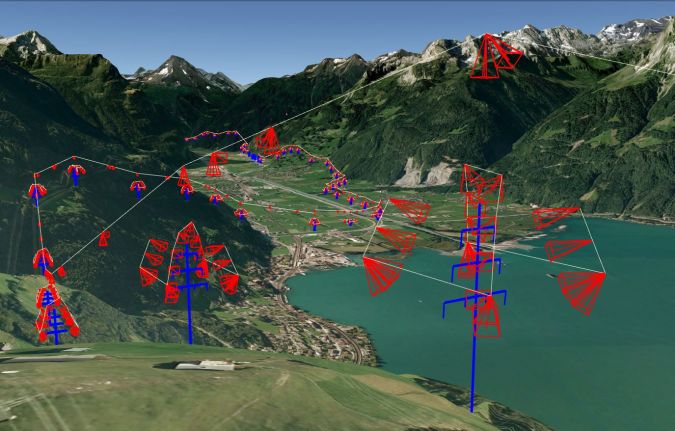

LINIA automatically calculates flight routes, based on digital line models (Figure 1). The drone app called LINIAair is designed to facilitate a smooth inspection process (Figure 2). Brief instructions for drone pilots are sufficient to simplify the data capture process. On site, pilots select the corresponding flight routes on the drone app and press ‘Start’. The drone, equipped with Phase One’s P3, automatically captures data until the battery runs low. Even the lens focus is automated, which guarantees that there are no blurred photos. During the flight, the pilot’s main task is to monitor the drone and the surroundings in case of emergency. One pilot and one drone are sufficient to do the job, but line inspections are often performed with two people for safety reasons. In this case, to increase productivity, the team can split up during the flight (when the topology allows it), with one person monitoring the drone and the second one driving the car.

One advantage of automated drone flights is the speed aspect. Depending on the size of the tower, it takes between three and five minutes to capture 20-30 images of a single TSO tower (220/380kV) and two to three minutes for a DSO tower (110kV). This means that the photos of three TSO towers or four to six DSO towers can be acquired during a single flight with 15-20 minutes of airtime.

Lorenzo Arizzoli-Bulato, founder of LINIA, states: “The daily capacity is limited by the time a pilot needs to relocate along the line. Last year, I once inspected 80 132kV-towers in a single day, although that was in very flat and easy terrain. In Alpine terrain the daily output is around 20 TSO towers per day, and in flat areas between 25 and 40 towers per day. These are good numbers, considering that manual drone inspection takes up to 20 minutes for a single tower, and this potential will further improve in the future when drones develop longer flight capabilities and the technology better supports BVLOS (beyond visual line of sight, Ed.) flights.”

However, speed is not the only advantage of automated line inspection. Other benefits include:

- Repeatability: The flight routes are repeatable in new inspection cycles. The images are very comparable because of the same position and perspective. This enables predictive maintenance.

- Structure: There is a standard structure for how the images are acquired. This structure provides full coverage of the whole tower and makes all imagery look similar, which is helpful for further data analysis.

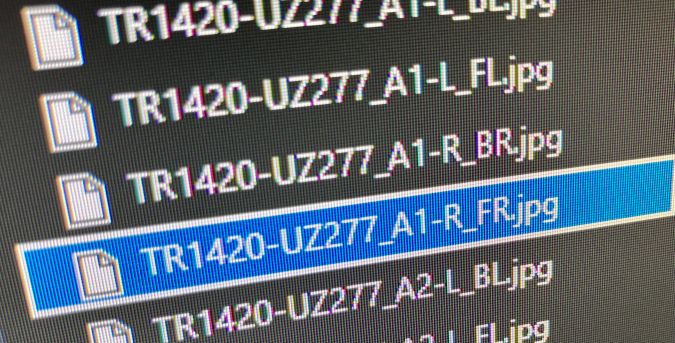

- Linking between photos and objects: The flight routes are based on digital line models. That connection is used to link objects, such as insulators, directly with photos. More specifically, each photo is renamed so that the name consists of information about the line, tower, crossarm and perspective (Figure 3). This metadata is used for further processing and enables proper data storage.

- Safety: Assessing the distance between the line and the drone is very challenging from a remote position, so there is always the possibility of human error when flying the drones manually. LINIAair is designed for line men, which means that basic drone knowledge is sufficient to execute safe drone operations. Automated and approved flight routes minimize the risk of mishandling the drone and improve the overall flight safety.

Summarizing the Benefits

Effective maintenance

The P3 and the iXM 100MP sensor have put efficiency at the forefront of Axpo’s activities. The company can now capture a series of high-quality images from different angles, detecting technical malfunctions and determining the precise GPS location of the assets. This supports predictive asset assessments, minimizing maintenance costs and disruptions to service.

Faster restoration of power supply

Compared to traditional methods, Axpo can now significantly reduce the time it takes to identify the fault and restore power in case of outages. Utilities can clearly see the problem via the imagery data provided, pinpoint the location using GPS and start working on a solution.

Significant cost reduction

Inspections are significantly faster and much more cost-effective, since the user-friendliness of the drone minimizes the labour involved and the number of site visits by trained professionals. Additionally, preventive repairs avoid unwanted (and costly) shutdowns.

Improved asset management

Better observation, detailed and long-term documentation and timely preventive repairs of critical areas are all crucial for long-term asset management. By significantly improving the quality of inspections, Axpo can ensure it has all the information it needs to manage and operate a first-class working energy infrastructure.

Eliminating inspection hazards

With the P3, Axpo can now safely inspect assets at dangerous heights, in high-voltage areas and in hard-to-reach locations without putting employees at risk.

Kevin Geiger, digital engineer drones at Axpo, comments: “Thanks to the Phase One P3, we can increase the efficiency of our power line inspections. We need fewer images, but we get more information and higher image quality. All this and more information are available in our data dashboard Insights inspectionand allow a detailed zoom function without a loss of the high resolution. Moreover, the integrated rangefinder feature ensures precise and fast focusing on every shot, thus enabling better standardization.”

About Phase One

Phase One A/S is a leading researcher, developer and manufacturer of medium-format and large-format digital cameras, software and imaging solutions. Founded in 1993, Phase One is a pioneer of digital photography. The company has developed core imaging technologies and a range of digital cameras and imaging modules. Phase One provides the world’s highest image quality in terms of resolution, dynamic range, colour fidelity and geometric accuracy. As such, Phase One has grown to become the leading provider of high-end imaging technology across many business segments. This includes both hardware and software for aerial mapping, industrial inspection and cultural heritage digitization, as well as serving the world’s most demanding photographers. Based in Copenhagen, Denmark, and with regional offices in New York, Denver, Cologne, Tel Aviv, Tokyo, Beijing, Shanghai and Hong Kong, Phase One nurtures long-term relationships with customers, technology partners and its global network of distributors, often playing the role of digital imaging partner to customers with special requirements. It is with this passion for service that Phase One continually exceeds expectations and drives the imaging industry forward.

www.phaseone.com

About Axpo

Axpo is driven by a single purpose – to enable a sustainable future through innovative energy solutions. As Switzerland’s largest producer of renewable energy and an international leader in energy trading and the marketing of solar and wind power, Axpo combines the experience and expertise of more than 5,000 employees driven by a passion for innovation, collaboration and impactful change. Through cutting-edge technologies, the company innovates to meet the evolving needs of its customers in over 30 countries across Europe, the US and Asia.

www.axpo.com

About LINIA

LINIA, a Swiss startup based in Zurich, is on a mission to increase the security of supply of power grid operators. With integrated software solutions, LINIA enables a digitalized inspection process that raises the inspection quality, speed and structure to a whole new level. As a result, grid operators save money and CO2 by reducing tower climbs and helicopter flights.

More information:

Phase One: Carsten Wieser

Axpo: Kevin Geiger

LINIA: Lorenzo Arizzoli-Bulato