Microdrones has taken yet another step forwards in drone solutions for aerial surveying, inspection and other mapping applications. The company’s new mid-market quadcopter system, the mdLiDAR1000LR, flies higher (up to 120m) and faster (up to 8m/s), capturing point clouds up to six times quicker and with greater precision and detail. The mdLiDAR1000LR payload includes, in addition to the Velodyne Ultra-PUCK VLP-32 Lidar sensor, a near full-frame-quality camera (the 26MP Microdrones CMOS APS-C) and the APX-15 unmanned aerial vehicle (UAV or ‘drone’) for georeferencing.

Thanks to the new mdLiDAR1000LR, operators can now simultaneously carry out a photogrammetry workflow while capturing the Lidar point data. The software has evolved too, for example, with a new algorithm that detects trees and vegetation which, if required, can be filtered out at a keystroke to reveal the bare terrain.

Longer-range Lidar data capture

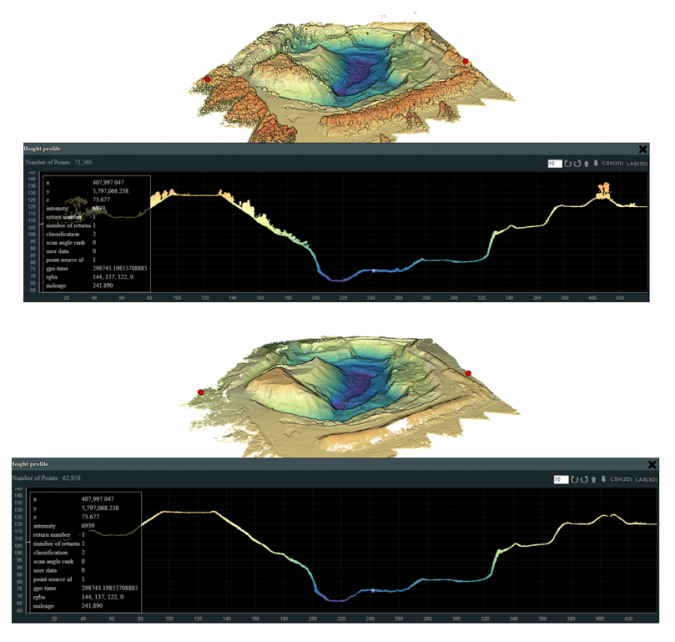

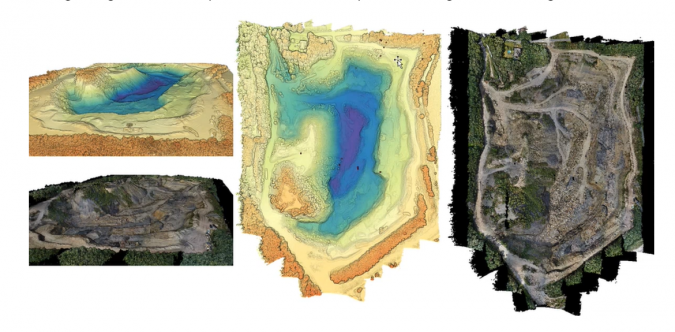

Microdrones recently used the new longer-range mdLiDAR1000LR to map a 15-20ha open-pit mine area with spots of thick vegetation, steep ledges and elevation differences of 60m or more. Flying at a constant altitude of 50m above the starting point (for a 110m difference from the lowest point to the flight height of the drone), the entire area was captured in a single 17-minute flight.

Tested by real users in the field

The demo was performed by UAV pilot and survey engineer Niels Flick from Flick Engineering, based in Ibbenbüren, Germany. Flick flew the same pit in 2020 using a mdLiDAR1000 with as payload a SICK LD-MRS4 Lidar sensor, FLIR 5MP Global Shutter camera and APX-15 UAV for georeferencing. “The new one definitely gives better data,” he said. “The new system was able to reach points on the ground and get data at 120m,” compared to 50-60m with the classic system.

Samuel Flick, a UAV expert at Microdrones, agrees. “There is new technology available that makes it easier and more efficient to fly such areas, compared to the first generation of Lidar products,” he said. For example, at a speed of 6m/s and a flight altitude of 120m, the mdLiDAR1000LR delivers an average point density of 123pts/m2. To achieve that precision with the SICK Lidar system, it would be necessary to fly at approximately 60m altitude and a slower speed, doubling or tripling flight times. “So this really is a new generation of Lidar sensor,” he stated.

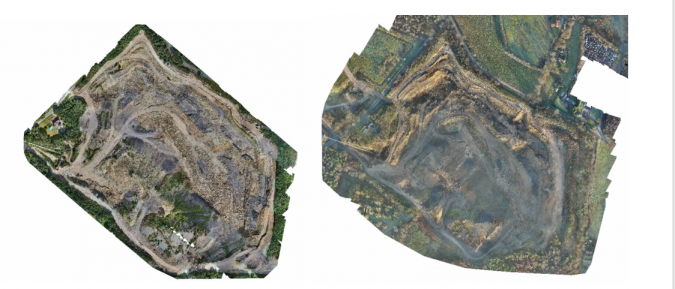

Photogrammetry workflow combined with Lidar point capture

One of the biggest advantages of the new system is the combination of the improved Lidar sensor with a near full-frame-quality 26MP camera. “So you don’t have to do another flight with the camera,” explained Niels Flick. The 5MP camera is fine for colourizing the Lidar point cloud and getting the supplemental images needed in certain projects. However, the new system’s 26MP CMOS APS-C camera produces a very good orthophoto as well, allowing for a full photogrammetry workflow without the need for additional flights.

Drone surveying is just one aspect of the surveying work done by Flick Engineering. “To measure large areas, it is the perfect tool,” said Niels Flick. His company has used the drone to document pit excavation, map the ground for new building sites and even for flood management reconnaissance.

Retrofitting

As a company, Microdrones has focused on providing end-to-end solutions consisting not only of the drone, but also integrated sensors, software, data extraction and processing. Its drones are built to enable sensors to be swapped out, so the airframe can in many cases serve multiple uses or be retrofitted to accommodate new sensor innovations. Full-service lease contracts are available for users interested in exploring the applicability of Microdrones’ systems for their own projects.