Mapping 21 Quarries in 60 Days

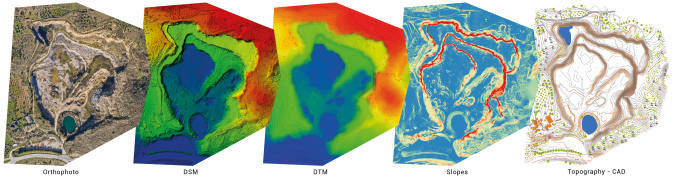

The mission was to capture 21 quarries in 60 days. Squeezed into that timeframe were planning and performing the UAV photogrammetry flights, editing the RAW images, processing the data, extracting the topography using Virtual Surveyor, and producing the orthophotos, digital surface model (DSM), digital terrain model (DTM) and contour maps for each site. The main client, a government institute, needed highly precise and reliable 3D models and maps fast, as well as data their engineers could work with in a CAD environment. “There was a lot of pressure because of the short timeline,” says Nuno Santos, owner and CEO of Aerisurvey, a company based in Mangualde, Portugal, specialized in high-precision surveying using unmanned aerial vehicles (UAVs or ‘drones’).

To get the job done, Aerisurvey used the mdMapper1000DG, a quadcopter drone (meaning that it operates on four propellers) produced by Microdrones. This German-based company was the first to commercially release a quadcopter reliable and rugged enough for professional applications. The drone has a flight time of up to 45 minutes and covers up to 80 hectares on one battery charge. For payload, it carries a Sony RX1R II 42.4 megapixel camera as sensor and an Applanix APX-15-L UAV inertial measurement unit (IMU) for georeferencing.

Setting Industry Standards

Survey datasets for the mining industry need to be reliable and accurate so that geotechnical people can base decisions on them. Among some companies, there is still a sense that only ground surveyors using total stations can deliver the necessary accuracy, and that drones and photogrammetry cannot deliver the resolution they need. Those impressions are changing with the emergence of equipment like the mdMapper1000DG, which Microdrones markets as a complete solution for surveying, construction, mining, precision agriculture and other geospatial applications. Aerisurvey was an early adopter of the technology which it has used since its establishment in 2017.

Approximately 60-70% of Aerisurvey’s current business is surveying for mining industry clients. For them, the ability to map large and small-scale features efficiently and accurately is key. Traditional surveying using ground-based techniques – such as total stations – is time-consuming, requires more surveyors in the field and can pose safety risks, since the equipment needs to be set up and the work conducted very near a ledge or at the bottom of the pit. UAV surveying enables difficult-to-access areas to be captured with better output quality.

Microdrones UAV systems offer easy operation, lower cost and better accuracy and repeatability. Software delivered on the system ensures that the drone lands safely in the home position, even if weather conditions change or battery power is low. With the mdCockpit app, operators have ‘tap and fly’ capability, which enables mission planning and monitoring as well as the repetition of flights and flight paths. Intuitive post-processing options are available for the collected data. The result is a simpler and more reliable workflow, so that larger amounts of data can be captured and processed more affordably, on a more regular basis.

A Mammoth Task

Once Aerisurvey received the go-ahead for the 21-quarry project, it faced a number of challenges. One was the weather, as the job had to be done in the rainy and windy months of December and January. Another issue was the holidays, as businesses tend to slow down and workers take vacation at that time of year. There was also the client’s request for the deliverables to be presented in the same way for all the quarries. This meant it would be difficult to work with other firms on the job, as every surveying company has its own processes and presents its outputs in a slightly different way.

Out in the Field, and Up in the Air

Quarry locations and topography presented challenges as well. The sites were spread over 900km, from Portugal’s far north (just 8km from the border with Spain) to near Faro in the far south. Some quarries were large (40-50 hectares) and had high vertical walls with elevation differences of up to 170m. Stronger winds at higher altitudes meant that a mission sometimes had to be postponed, even when ground conditions seemed favourable.

Ultimately, Santos flew the missions single-handedly and carried out most of the data processing himself. This remarkable accomplishment has made the project somewhat of a showcase of the power and reliability of the Microdrones system. “Reliability is everything in drones,” continues Santos. “When I look back, the volume of fieldwork and the data produced was insane. I drove 12,000km in 60 days, working 12 to 16 hours a day.”

Because the timeline allowed just three days for each quarry, Aerisurvey really had to rely on the equipment. “Fortunately, we had the mdMapper1000DG from Microdrones,” he adds. “We never had a single issue.”

Commitment to Precision

One of Aerisurvey’s core values is data precision. “We would never deliver a survey with an RMS error greater than one pixel,” states Santos. Though the company did use checkpoints and ground control points (GCPs) for the quarry survey project for its own quality control purposes, the mdMapper1000DG offers the option of direct georeferencing (DG), which eliminates the need to install any GCPs.

To test the feature, Aerisurvey conducted a trial with a ground sampling distance (GSD) of 2.5cm and achieved 2.5cm precision without GCPs. Anyone would consider a root mean square (RMS) error equal to the GSD a good result, according to Santos, so that’s an impressive outcome. In that case, using GCPs reduced the error to 1.3cm. “We don’t see that kind of precision and accuracy on any other system,” he comments. “Companies need to see the data to believe it. Once they see the data, they are more than convinced.”

Bringing Out the Best in Photogrammetry

Aerisurvey is one of the relatively few companies, as yet, to implement advanced work processes and capabilities to bring out the best that photogrammetry can offer for surveying deliverables. On this, it has collaborated with the University of Coimbra, which is an academic leader in photogrammetry applications in Portugal, with more than 80 papers published on the topic.

For example, Aerisurvey always captures images in RAW format. These require more computing power to process, but the output is infinitely superior. “When you only shoot in JPEG, you lose data,” explains Santos. Data loss is a particular problem in quarries, as deep shadows cast by walls often appear in the same frame as brightly lit areas such as stockpiles. Using a good full-frame sensor enables both shadows and highlights to be recovered on images acquired in RAW format.

The same scene captured as JPEG (a) and captured in RAW format and edited (b). When shooting in JPEG, data is lost. Using a good full-frame sensor, both shadows and highlights can be recovered on images captured in RAW format.

Editing photos individually to create layers is another best practice for producing high-quality orthophoto maps. To guarantee that the white balance is perfect and not greenish or yellowish, Aerisurvey uses a technique from professional photography: a simple colour card. By taking a picture of the colour card before and after each flight (for a record of current lighting conditions), the images can be edited later to match what the eye sees visually.

Deliverables as a Point of Pride

Such high-precision, colour-correct outputs deserve to be seen, not only by engineering departments, but also by CEOs and departments that do not work with the raw data. Presentation of project deliverables is another area where Aerisurvey is leading industry standards. For the quarries – as for all Aerisurvey’s clients – the company produced printed and bound reports, 3D models and aerial footage videos, along with an A0 poster of each quarry site on fine-art photographic paper.

The poster, in particular, elicits positive feedback. These large, very accurate and detailed printouts find unexpected uses, according to Santos. Standing around a table looking at a proper print gives operational people a good sense of what they are doing. That can result in improved work processes within the client organization too.

[Streamers]

“We pushed ourselves to deliver a standard, which became a standard. Now we have even more confidence to say we can do it.”

“We are a small company. We need to choose the right tools, like the mdMapper1000DG. Even if that means fewer tools, the best tools give our clients the best results. Quality is always the way to go.”

Project Specs |

|