Industrial Vision Metrology Supports Power Plant Renewal in Japan

The first commercial nuclear power plant began generating electricity in Japan over thirty years ago. There are 55 reactors in seventeen plants currently in operation and one third of Japan’s electricity is produced by nuclear power. The ground in Japan is relatively fragile and subject to frequent and rampant earthquakes. Therefore power plants have to be carefully maintained. Built in the 1980s, most power plants today need thorough renewal. Any such process has from beginning to end to be accompanied by precise 3D-measurements.

Wasteful Procedures

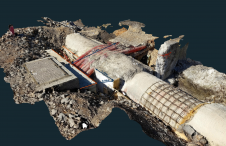

During the renovation process, huge installations and the many pipes connected to them must be replaced within a limited time-span and in a highly radioactive environment, fully by remote control. Replacements for installations are first fixed and their flange positions measured. New pipes are manufactured later to fit the flanges. All measurement and fixation has again to be done fully by remote control. The conventional procedure is to copy the relative position of flanges using a special device and continue to copy until levels of radioactive contamination fall low enough to be able to bring parts to a factory. Such a procedure results in large volumes of waste.

Cost and Time Saving

A total station or laser tracker cannot be applied in remote-control works. Instead, industrial vision metrology was recently adopted for renewal of a fuel-reprocessing plant. Some pieces of equipment weigh over 20ton. Vision metrology means intermediate waste is minimised and the volume of final waste reduced to a third. Further, vision metrology enables huge cost savings and dramatic reduction in renewal time. The next target is a power plant. Heavy industry in Japan is now looking to vision metrology for maintenance and renewal of power plants and reprocessing plants.

Customisation

Industrial vision metrology systems VSTAR (GSI), Icam (Imetric 3D Corp.), some local systems and others are already on the market. One problem is that it is very hard for manufacturers to provide a complete off-the-shelf system for application in any plant situation. Hence quick response and careful customer support may prove key to successful sales in Japan.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)