Low-cost UAS Photogrammetry for Mining

Exploring Consumer-grade Copters for Quarry Mapping

Unmanned aerial survey (UAS) photogrammetry has proven to be a good alternative for capturing open-pit mines, but it is expensive when done professionally. This article investigates whether low-cost UAS photogrammetry, using consumer-grade copters, is sufficiently accurate for 2D and 3D mapping of quarries based on a project in Ukraine.

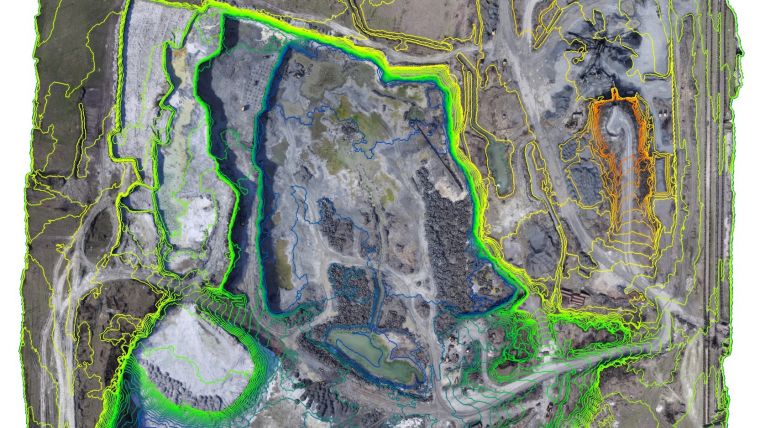

The Rafalivka basalt quarry, located in the Rivne region of Ukraine, produces just over a quarter of a million tonnes of crushed stone and gravel each year. The quarry covers over 70 hectares, of which 36 hectares are actively exploited today, and its depth reaches 50 metres. Surveying from the ground is not only cumbersome and tedious because of the large extent of the area, but also because many parts of the quarry are inaccessible. For example, accurate calculation of the extracted gravel volumes requires coordinates of sufficient points on steep slopes and ledges (Figure 1). Furthermore, since ongoing earthworks often destroy ground control points (GCPs) and targets, monthly checks and repairs of the geodetic reference system are required. Besides that, there are of course safety considerations; ledges are unstable, and the heavy machines make a lot of noise as they continuously move around, posing an accident risk.

Low-cost Copter

Capturing the area from the air helps to resolve these problems if proper hardware and software is available. UAS photogrammetry has been applied all over the world for capturing open-pit mines. The quality and usefulness of the geodata obtained are affected by weather conditions, magnetism and other natural forces. While professional solutions are robust against the impact of extreme temperatures, gusts of wind and other environmental conditions, they are also pricey. This raises the question of whether consumer-grade copters equipped with cameras are able to deliver geodata products of sufficient quality. To answer this question, the authors carried out a case study using the low-cost DJI Phantom 3 Pro quadcopter, which can be purchased for around USD1,000 and is equipped with a 12MP camera with fixed focus. The latter is advantageous because it contributes to the stability of the interior orientation parameters of the camera. The copter can stay in the air for half an hour on one battery charge, which allows the coverage of a relatively large area in one flight. Using Pix4D or DroneDeploy software, a flight plan can be preprogrammed which allows images to be captured in automatic mode and eases the planning of the photogrammetric survey.

Survey

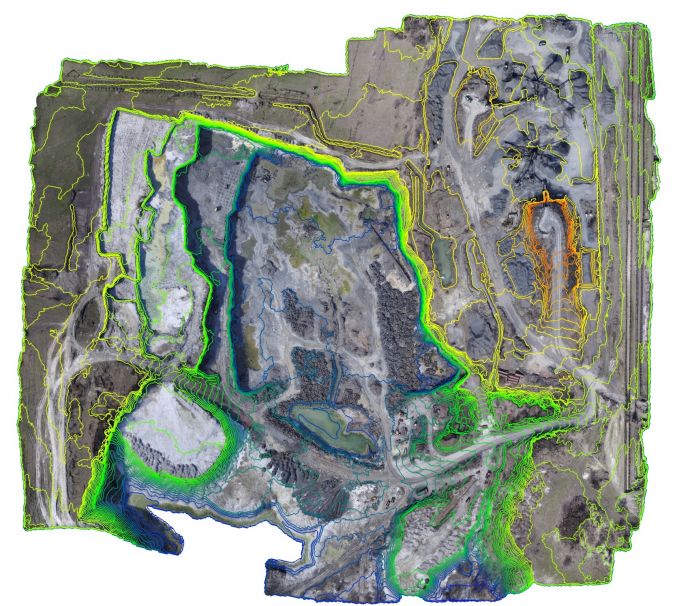

The authors planned to cover the area with two flights of 30 minutes each at a flying height of 120m to obtain a ground sampling distance (GSD) of 5cm and 80% along- and across-track overlap. However, at the time the survey was conducted, the temperature had dropped to below 15C° which was too cold for the battery to provide sufficient power. That problem could be solved by warming the batteries in advance, but then a second problem arose: a strong wind which blew over the quarry with a speed of over 10m/s. Once the UAS had reached the planned flying height of 120m it was caught by the wind. To avoid the UAS deviating too much from the preprogrammed path, the flying height was lowered to 60m where the wind was less strong. However, as wind affects power consumption, this halved the flight time from 30 to 15 minutes, thus increasing the number of flights necessary to cover the area from two to six. Nevertheless, it was possible to complete the survey within one workday (eight hours) with only two batteries. By the end of that day the copter had flown over 12km and covered 36ha, capturing 1,324 images with 90% overlap and a GSD of 3cm (Figure 2). Since GCPs were necessary to georeference the images and derived products in the local coordinate system used, 11 GCPs were placed at the edges of the quarry and their coordinates measured with a total station. Seven temporary GCPs were measured in the centre of the quarry aimed at computing accuracy statistics, also with a total station.

Data Processing

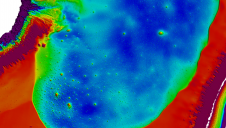

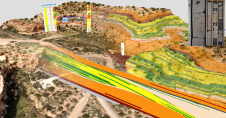

Photogrammetric data processing includes calculation of the focal length, principal point and other camera parameters, triangulation and georeferencing, and image matching for the creation of a DSM point cloud from which a digital elevation model (DEM) can be derived by removing non-ground points such as vegetation, buildings, vehicles and quarry machinery. Other derived products include orthomosaics, contour maps and volumes. If more than three GCPs with reliable coordinates are available, the camera parameters for each exposure can be adjusted reliably; in this project, this was done by using all 18 GCPs. This study showed that the camera parameters remained stable over time.

The main problem concerned the many images. According to software specifications, high-quality calculation requires around 128GB of RAM. The processing was done on two computers: (1) a desktop with Core i7 processor, 64GB of RAM and a GTX980Ti graphic card (USD2,000); and (2) a laptop with Core i7 Mobile processor, 8GB of RAM and a GTX 960M graphic card (USD800). Processing took seven hours on the desktop computer and 26 hours on the laptop. The 64GB of RAM of the desktop computer enabled exploitation of full-resolution images, whereas the laptop could only process the images at half-resolution. The lower resolution did not significantly affect the positional accuracy; the difference was less than 3cm. The main difference was in the level of detail. The point cloud with 232 million points was used to derive other geodata products including a 3D mesh model (Figure 3), orthomosaic, contour lines (Figure 4), volume and 3D map of the quarry.

Accuracy

A comparison of the coordinates of the seven GCPs used as checkpoints and the corresponding points in the DEM shows a planar error of 5cm and a height error of 10cm. The 3D root mean square error (RMSE) appears to be approximately 7cm. According to national standards, topographic maps of quarries are at a scale of 1:500, 1:1,000 or 1:2,000, depending on the size of the quarry. The associated accuracies are 15cm, 30cm and 60cm, respectively. Hence, the accuracy obtained in this study is well within the standards. Comparing volumes measured periodically allows computation of the amount of rock extracted per period and this is the main indicator of productivity and profitability. The high accuracy of the DEM allows accurate volume determination of specified parts (Figure 5). Taking into the account the accuracy of the DEM, the root mean square error (RMSE) can be computed (Table 1).

|

|

Volume |

RMSE |

Deviation |

|

|

7,264.45 m3 |

±35.84 m3 |

0.49% |

|

|

5,661.45 m3 |

±29.78 m3 |

0.53% |

Table 1, Computed volumes of two parts of the quarry and accuracy assessment.

The national standards of Ukraine permit deviations of 15% for volumes up to 20,000m3 to 4% for volumes of 500,000m3 and larger. Ground surveys carried out by highly experienced surveyors usually result in deviations of 10% to 2%, respectively. This is due to the complexity of the shapes of the quarry surfaces. This case study shows that the approach is able to limit the deviations to around 0.5% for volumes less than 20,000m3. Thus, the results demonstrate that low-cost UAS photogrammetry produces results which are significantly better than the standards prescribe, and for larger volumes this relative error will be even smaller.

Efficiency

This survey covered the entire quarry, but such a complete survey is actually needed only once in three to five years. Digging is usually performed in just a small part of the quarry and that is the only part which has to be captured regularly, e.g. once a month. This significantly reduces flying time and the number of images needed to cover the area under exploitation, meaning that the on-site survey takes a maximum of one day and the data processing takes only two to three days. Hence, one survey team can capture three to four quarries in the space of one month. The accuracy can be further increased and the survey time reduced by placing permanent GCPs in the parts of the quarry which are exploited.

Concluding Remarks

This approach is efficient for periodical surveying of small and medium-sized quarries. If an open-pit mine is larger than 50ha, a low-cost UAS survey takes too long plus the sheer amount of images becomes hard to process. Therefore, other methods are preferred for larger areas.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)