Lead’Air Launches 360-degree Coverage Survey Camera

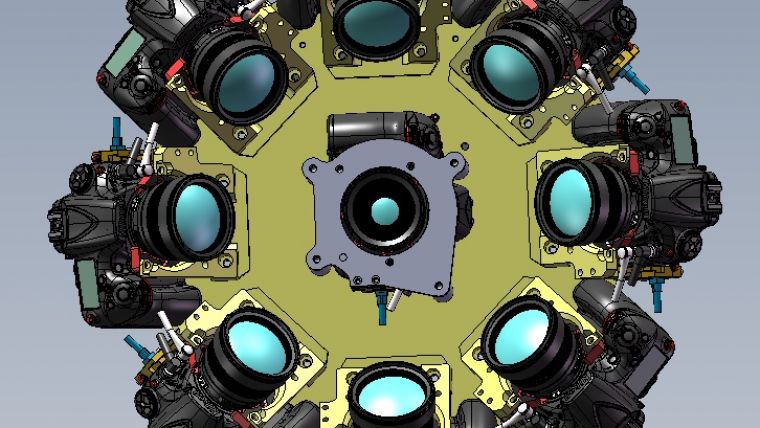

Lead Air, the manufacturer of Track’Air aerial survey products, is unveiling a new 9-camera MIDAS system with 1 vertical camera and 8 oblique cameras covering a true 360 degrees. Instead of the classic arrangement with 4 oblique cameras, facing forward, backward, left and right, the new Octoblique MIDAS adds 4 additional oblique cameras which fill the gaps, thus doubling the amount of oblique photos collected without an increase in flying time. With 8 cameras spaced at 45 degrees from each other instead of 4 cameras spaced at 90 degrees, the Octoblique looks in all directions around the aircraft and generates twice as many oblique views as any other system, leaving no angular blind spots uncovered.

The addition of 4 cameras was made possible by a new patented ground breaking fully stabilised camera suspension system. This innovative system allows the 8 cameras to move freely, soaring at a very short distance above the aircraft camera port, without the need for a bulky old-fashioned circular mount. Instead of using very costly medium-format cameras, Lead'Air uses economical off-the-shelf, full-frame, top-of-the-line SLR bodies from Nikon and Canon. These cameras are entirely reengineered and rebuilt in its own facility. They are reassembled using the best available lenses into true metric mapping cameras which are each delivered with an official calibration certificate.

New standards

Jean-Pierre Barriere, president of Lead Air, describes the new Octoblique system as a disruptive technical advancement which will rapidly set new standards in the oblique aerial photo business. Instead of increasing, at high cost, the sensor size of the 4 oblique cameras, they have increased the overall capture extents of the entire system. This allows the Octoblique system to be flown with less lateral overlap, therefore less photo lines and less operational costs. Where a 4-camera oblique system, regardless of its sensor size, requires 60% or more lateral overlap to insure coverage between high buildings, 30% lateral overlap is enough for an 8-camera oblique system, which in turn brings a corresponding reduction of the operational costs.

Joe Bima, president of Stellacore Solutions, who has been instrumental in the development and testing of the Octoblique system, adds that with 5 viewing directions only, some features miss optimum coverage. With 9 viewing directions, not only is optimum coverage of such features achieved, but there is the benefit that all features result in a more robust information-rich coverage/capture. It is this greater information-rich capture that the end market and applications can/will benefit from. There will be more information that more accurately represents the world to extract better data in virtual inspection applications, virtual reality applications and 3D modelling, Bima continued.

Flying time

Greg Montgomery, director of DatAir flight missions at Williams Aerial & Mapping, who conducted the airborne trials of the Octoblique, concluded that a 9-camera system not only offers a more robust 'aerial captured reality' of the world at half the cost of others expensive 5-camera oblique systems, with no added flying, but the vastly improved coverage allows a significant reduction of the flying time. Thanks to the reduction on lateral overlap requirements, they can now save up to 30% of their flying costs. With oblique projects which can double or even triple the amount of photo lines compared to traditional vertical mapping project, the benefit of operating 9-camera oblique systems is essential for the aerial operation.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)