Leica Geosystems, HDS

Fifth User Conference and HQ, San Ramon, USA

Terrestrial laser scanning combines a high level of detail with surveying accuracy for the creation of 3D-models of virtually any object. The technology literally opens up new dimensions and so attracts widespread attention. It is in the interest of manufacturers to bring these people together for cross-fertilisation of ideas, so to drive the makers on towards problem solving and new survey solutions. Leica Geosystems HDS held the fifth such get-together in California from 22nd to 24th October 2007.<P>

Arriving tired and tense after an intercontinental flight, the journey from San Francisco International Airport to San Ramon feels fraught. After a ninety-minute train trip on the BART (Bay Areas Rapid Transit) “blue line” to the Dublin/Pleasanton terminal, it takes another twenty minutes to get to the Marriott Hotel, venue for the fifth Leica Geosystems HDS User Conference. The hotel is in the middle of a business district; ten minutes’ walk from Leica Geosystems HDS headquarters. The ice-breaker reception provides an opportunity for me to meet Geoffrey Jacobs, senior vice-president strategic marketing, and moderator at the event. In the US, Geoffrey is widely considered a leading expert in the laser-scanning industry, a reputation probably due in part to his authoring more than thirty feature articles published in our US sister magazine, Professional Surveyor . His articles cover a wide range of business and technical aspects, and conference participants were later to confess their ‘understanding of laser-scanning technology and its business opportunities started much from reading Geoffrey’s articles’.

Market Growth

Monday morning, and Dr Juergen Dold, introduced by Geoffrey Jacobs as Leica head of imaging and scanning business, kicks off the conference. ‘Terrestrial laser scanning (TLS) or High-Definition Surveying (HDS), as we at Leica have redefined the technology, is a market which has rapidly grown in the last four years, and the growth will continue’, he predicts. A diagram showing year as horizontal axis proves exponential development in the number of laser scanners installed by Leica from 2000 onwards. Aligned with the vertical axis is the term “unit”, without quantification. Another slide illustrates greatest usage of Civil and Plant applications. Later presentations underpin this. For example, Bill Campbell, General Motors Corporation, Detroit, discusses how 3D as-built models created with TLS are used in plants all over the world. Engineers and suppliers thus gain instant access to the data via the web, using Leica’s free TruView software.

Heritage

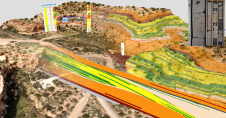

Acknowledging growth in the Plant segment, Tuesday afternoon saw two parallel tracks, one on Plant and the other on Civil/Survey/Architecture. The strong rise in Plant is in part driven by the 2006 release of the HDS6000, a phase-shift scanner which can measure up to 500,000 points per second. ‘In the building sector, including architecture, facility management and heritage documentation, market size is of medium level, although the longer-term potential is significant,’ Dold continues. Nevertheless, products in this segment can be very impressive, as Doug Pritchard, head of Visualisation at Glasgow School of Art in Scotland demonstrated in his presentation of highly detailed, photo-textured 3D-city models of Glasgow, a project funded by the European Union. The models were created by two scanning surveyors and six, sometimes eight, modellers, over about an eighteen-month period, starting in the summer of 2006. ‘Glasgow is an old city with many narrow and curved streets, so 3D-modelling needs substantially more time than for a new city like Toronto,’ Pritchard explained. Heritage documentation is not so much an industry as a university research activity. During lunch on the first day Prof. Carlo Bianchini of the University of Rome, Italy, presented an overview of his work documenting some of the world’s greatest heritage sites, including the Coliseum and Antonio da Sangallo’s wooden model of a design for St. Peter’s Cathedral, which was never built. He also showed, for the first time in public, scans of the interior of today’s St. Peter’s Cathedral. On the Wednesday of conference his co-worker, Alfonso Ippolito, discussed findings and developments to model complex structures such as domes.

Accidents and Forensics

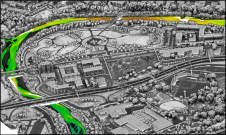

The police and the military also benefit from TLS for such applications as traffic-accident survey and forensic research. This market is not so extensive as Civil and Plant, and growth potential is medium. Lieutenant Dave Fox, Highway Patrol (CHP), California, gave an impressive presentation on accident surveying, ‘Each accident scene needs to be surveyed quickly, accurately and completely. Seeing the potential of TLS, in 2006 we bought no fewer than five scanners.’ Fox went on to highlight an extraordinary road accident which took place in the early morning of 29th April 2007 on an approach to the San Francisco-Oakland Bay Bridge. ‘A tanker truck carrying over 30,000 litres of gasoline crashed and went up in flames. The heat caused an overpass to collapse onto an interstate (highway) below.’ A few minutes later CHP’s Multidisciplinary Accident Investigation Team (MAIT) was on site and scanned the overpass from ground to top, assisted by Leica engineers. According to the MAIT team manager, ‘With conventional means we collect just five hundred to a thousand points, with laser scanning, millions. And it is fast and safe, as unsafe positions can now be measured remotely. Also, the road can be reopened sooner, and high detail and accuracy allows not only accident reconstruction but is also useful for civil engineers.’ Craig Fries, founder and principal of Precision Simulations, showed convincing examples of how crime scenes could be reconstructed by combining laser scan data taken after the crime with forensic information. Scanning is contracted out to surveyors. Using point-cloud-processing software Cyclone and other tools, simulations of the past are created and taken to court. Such simulations are extremely visually convincing, imitating the realism of film, and so often convinces juries that this is how it happened.’

Cyra Technologies

Laser scanning is not an autonomous development on the part of Leica but was introduced into the company through acquisition of Cyra Technologies in 2001. Cyra founder Ben Kacyra has a background in civil engineering and graduated from the University of Illinois in 1965. In 1973 he co-founded Cygna, an engineering company in San Francisco offering design and construction management services. After the merger of Cygna with another US-based firm in 1989, Mr Kacyra founded Cyra Technologies in 1993 in Oakland, California. ‘The idea of developing and producing laser scanners stemmed from his engineering and construction background,’ Geoffrey Jacobs tells me. ‘There he saw that as-built surveys were carried out by large groups of field workers basically making manual measurements using tapes and theodolites and still producing incomplete and inaccurate drawings of complex piping and structures. This could be done faster, easier and better using advanced technology!’ The resulting measurement system, Cyrax, was brought to market in 1998; a year later, thirty instruments had been sold. The success of the system attracted the attention of bigger players, and so it was that in February 2001 Leica Geosystems acquired Cyra Technologies, since April 2004 formally named Leica Geosystems HDS Inc and based in San Ramon, California. The year 2001 marked, incidentally, the highest number of acquisitions since Leica’s founding as Kern and Co in 1819 in Aarau Switzerland. Leica not only bought Cyra but was also augmented by Laser Alignment Inc, Grand Rapids, MI, and ERDAS, Inc, Atlanta, GA, while the remaining 50% of LH Systems, San Diego, were also acquired. Although financially well positioned, Ben Kacyra did not retire but realigned the letters of his family name and founded non-profit organisation CyArk. Recognising the threats facing the world’s most valued cultural heritage sites, CyArk collects accurate, digital 3D-models by TLS and stores them in a publicly accessible archive( http://archive.cyark.org ). CyArk’s main sponsor is the Kacyra Family Foundation, formed to foster humanitarian, cultural and scientific endeavour in heritage, medical research, human energy and education.

Market Leader

‘Today we are acknowledged as the market leader in laser scanning; we have shipped almost 1,500 scanners,’ Dold tells me. ‘This is not only a result of the take-over of the best laser-scanner manufacturer and software developer at that time, although it contributed a lot; the people with Cyra all were excellent researchers, engineers and developers. It is also because Hexagon, the company who owns Leica Geosystems, wants to remain the leading manufacturer over the entire measurement space, from micrometre to kilometre.’ As a result, the company invests heavily in research and development. ‘We deliver to our customers what we promise; we do not need exaggerated marketing efforts to convince our customers. Quality, high service and support levels, and successful users are our best marketing.’ In response to my asking him why he had introduced the term “High-Definition Surveying” to identify the technology, rather than using a conventional term like Terrestrial Laser Scanning, he elaborates in detail. ‘The term HDS appeared on the horizon when we had to think about a name change for the predecessor of Leica Geosystems HDS. The need for renaming popped up because Cyra Technologies became closely integrated with other parts of the company. The HDS3000 laser scanner, the first to have the look and feel of a survey instrument, was jointly developed by the teams in Switzerland and California, and sales and support goes along Leica lines. The terms High-Definition Surveying and HDS were formally introduced at the Intergeo 2003 conference. HDS clearly expresses how the technology differs from other geometric data-capture methods in terms of capturing detail, and it was quickly accepted and picked up by customers. The term also received strong support from editors of leading industry trade publications. The term perfectly describes where we are going to with this exciting technology. Our application for registration of “HDS” as an International Trademark was approved by many of the countries with which we do business. So we renamed the division “Leica Geosystems HDS Inc” in 2004.’

Calibration and Repair

I accompany Mathias Svensson, Stefan Nyberg and Peter Berg, all of Scandinavian energy-provider Vattenfall, in a short car journey to Leica Geosystems HDS headquarters. On the way Mathias Svenson tells me a little about the Sweden-based Vattenfall, founded in 1903 and transformed in 1992 from a public energy provider into a state-owned company. The company uses laser scanning for rebuilding and documenting plants, for simulation and visualisation of new constructions and emergency projects, and also for logistical planning and time schedules. We are welcomed to HDS by Hendrik Bartel, product manager. ‘San Ramon houses the Leica Geosystems HDS HQ and a services department, but manufacturing of laser scanners is now completely done in Switzerland. That is a well-considered choice. Before Hexagon took over Leica in 2005 the production of airborne laser scanners had already been moved from Massachusetts, US, to the main manufacturing plant in Heerbrugg, Switzerland; terrestrial laser scanners followed the same route.’ Dennis McLaughlin, director of manufacturing, adds, ‘The move to Switzerland is a very natural one. There we have all the expertise available for manufacturing instruments. In addition, although Switzerland is not the cheapest spot on earth, the San Francisco Bay area is known for its exceptionally high manufacturing labour costs. Yes, my business card still tells me I am director of manufacturing, but “product innovation support” would be the better term, because that is what we focus on and we are here running a state-of-the-art test, calibration and repair facility. So our customers in the Americas will still be able to get prompt service and support.’ Indicating the laser scanners on show in the reception hall, Dennis McLaughlin goes on, ‘ScanStation 2 was introduced July 2007. Although it looks from the outside very similar to ScanStation 1, at 50,000 points/sec scan speed, it is more than ten times faster than its long-range, time-of-flight predecessor.’ In November 2006 the compact HDS6000 was announced as successor to the short-range, phase-based HDS4500 scanner. (Check GIM’s Product Survey on Terrestrial Laser Scanners, August 2007, vol. 21, no. 8.) Dennis continues, ‘Our scanners can operate everywhere on earth, as long as the air temperature is not too far below zero and not above fifty degrees Celsius. Sub-Saharan Africa and other tropical countries are no problem; the instruments can cope with high humidity, but rapid change of humidity is an issue.’ He ushers us into the calibration hall, a huge room where the tuning parameters of scanners are accurately determined. ‘Laser scanners are like individuals,’ he says. ‘Each has its own character, and to get acquainted with that takes a lot of time. So laser scanners are subjected to our full attention over a twelve-hour periodand the resulting parameters quantified and stored onboard.’ To avoid having to go outside for testing, the company has installed an indoor test-range over 100m in length.

Error Analysis

This user conference does not include many mathematical presentations; it is, as its name implies, a meeting of users and not a gathering of scientists. But during one presentation on estimating error when measuring between two scan data-points in TruView software, the presenter, a Leica expert, confirmed the preconception that American knowledge of maths is somewhat underdeveloped. His slides included a lengthy “derivation” to demonstrate that the standard deviation (SD) of the outcome of the sum of two parameters can be obtained by taking the SD of one of the two and multiplying the result by 1.4, provided that the size of both SDs are similar. Although this is not incorrect, one wonders why error propagation need be deconstructed to such an elementary level, clarifying nothing while endorsing a misconception all too often present in the heads of laymen, that is that standard deviations can be summed up. When R = P+Q, the standard deviation of R (SDR) reads square root of (SDP2+SDQ2), with SDP and SDQ standard deviations of P and Q respectively. When SDP and SDQ are similar in size (i.e. SDQ = SDP) then SDR reduces to the square root of 2 SDP2, which equals 1.4 SDP. And that's about it, folks!

Final Remarks

Many survey companies feel the need to take the step into TLS, but there is still much to learn and much uncertainty. Sometimes it is better to share experience and carry out a co-operative project with two or three firms. Some companies were in San Ramon because they were considering making the move towards exploring the technology as part of their services. Total registration for the fifth user conference was close on three hundred participants from seventeen countries, an increase of 25% over last year. At the end of the conference Juergen Dold announced plans for another such conference in 2008, probably also in October and in the US, location to be announced. Back to my opening complaint: another site would do the next conference no harm!

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)