Lidar: Quality Assurance and Control

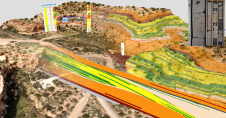

Lidar systems have been widely adopted for the acquisition of dense and accurate topographic data over extensive areas. Collected topographic data can satisfy the needs of several applications, such as environmental monitoring, contour mapping, transportation planning, emergency management, military simulation, ortho-rectification, oil and gas exploration, mining, hydrology, shoreline management, 3D city modelling, and forest mapping. This article presents the author’s suggested road map towards the development of commonly accepted procedures for ensuring and verifying the quality of derived products.

Best Practices

As in any mapping activity, a set of commonly accepted best practices need to be established to ensure the quality of products derived from Lidar systems. These practices include pre-mission procedures, labelled Quality Assurance (QA), and post-mission procedures denoted Quality Control (QC). QA activities include the system calibration process and flight configuration necessary to achieve certain characteristics, for example point density, positional accuracy, and minimal gaps. QC focuses on the quantitative inspection of Lidar data to verify whether or not the desired data characteristics have been achieved. In spite of the widespread adoption of Lidar mapping, standardised QA/QC activities have not followed suit. For example, Lidar calibration is usually conducted through proprietary procedures which depend on the system manufacturer as well as the expertise of personnel in charge of the calibration procedure. On the other hand, a frequently adopted procedure for quality evaluation is the comparison of Lidar data and ground-control points. Besides being expensive, this approach is not accurate enough for verification of horizontal accuracy unless specifically-designed targets are utilised.

Clear Understanding

The development of effective QA/QC procedures for Lidar systems and derived data should be based on a clear understanding of the sensor model. In other words, the user community should have a good handle on how system measurements and parameters are integrated to derive ground coordinates of the point-cloud. In addition, it is necessary to recognise the impact of systematic and random errors in system parameters and measurements on point-cloud coordinates. Having developed a clear understanding of these issues, the following may be decided:

- parameters to be considered in the system calibration process;

- possible scenarios for system calibration; capable of performing calibration while considering the nature of available data to the end user

- appropriate flight and control configuration for accurate system calibration

- appropriate QC procedures; effective, practical and economical quality-control procedures should be developed to evaluate and quantify systematic discrepancies and noise level in acquired data.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)