The Challenge of Change

SBG AG

SBG, a Sweden-based privately owned company, designs and manufactures software and hardware for survey, design, and machine-control applications. Since its inception in 1970 the company has provided surveying tools for the office, package solutions for field surveying equipment, and systems for machine control.

SBG started out at a time when surveying and machine control in Sweden was somewhat in its infancy. The company, and indeed the entire field of surveying, has come a long way since then. But whereas methods and technology may have changed, the vision and commitment to quality and innovation that propels the company forward has remained essentially the same. Despite the success of recent years, in many ways SBG retains the hallmarks of a small family business. Our customers are still construction companies, as when, at our humble beginnings, SBG was a pure surveying consultant company and the client list had not yet grown to include other surveying consultants, municipalities, contractors and land surveying offices.

Innovation

Still president of the company he once founded, Sven Vejde is both an inventor and an entrepreneur. The first invention at SBG was a machine that automatically made stakes from timber. In the mid-1970s the first surveying software was released, made for HP calculators. An important part of business in the1970s and 1980s was plotting of drawings. Before plotters were yet available on the market, Sven created and designed his own A0 plotter. In the mid-1980s the first field computer connected to a total station was released under the name GeoPad. When the auto-tracking total station was brought to the market at the beginning of the 1990s, dreams of using a total station to control machine hydraulics started to become reality. In 1995 SBG promptly launched the GeoROG, one of the world’s first 3D machine-control systems.

SBG Products

We currently offer the following software and hardware solutions:

- GEO, a PC program for geodesy and surveying which includes functions for every step in design, setting out, surveying and reporting; additional modules for road lines, volume calculation, terrain models, tunnel handling and net adjustment make Geo a complete geodesy system

- GeoPad, a hybrid numerical and graphical system for field surveying work, available for a wide selection of handheld computers; the system is compatible with total stations and GPS from all leading manufacturers and comes in two versions: professional and site navigator

- GeoROG, a 3D machine-control system, in production since 1995, that offers better project economics through transparent cost control, streamlined material and HR expenses, and significantly improved performance and precision.

Brand Independence

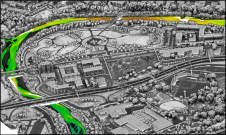

With 24 employees, the current priority markets are in Europe and Australia. Brand independence is a key aspect of the entire product line, and part of our culture. All products must be able to connect to any GPS-receiver, total station or 2D-machine control system to our satisfaction. In 2005 our efforts to create and deliver excellence were rewarded when we became the 3D-system supplier of choice for delivery of fifty GeoROG machine-control units for guiding the machinery on the Skanska A1 motorway project in Poland, Europe’s largest road-construction project. This contract, the biggest in our history, is worth an estimated US$570 million and also includes GeoPad handheld mobile devices and several Geo office software licenses for construction workers, surveyors and engineers.

Shifting Role

In Scandinavia we’ve seen a huge change in the role of the surveyor, especially on big infrastructure projects. This is because of the increasing use of 3D machine-control. Instead of the hard work of setting out stakes, the job concerns more preparing and checking models for machines. Another change is the maintenance of the GPS receiver and 3D computer on the machines. Today’s construction and surveying projects show a dramatic increase in quality insurance work. Instead of calibrating the total station, the surveyor now has to calibrate an excavator. The shift in the surveyor’s daily tasks also includes checking the models before transferring them to the machines. Another key issue is data flow from design through the construction phase to as-built. Because this aspect of today’s projects involves many people, and because operating procedures differ from one nation to another, this has become a real challenge, perhaps the biggest of all. The design-phase will be more expensive if done in 3D and according to surveyor preference, but if the design can be imported directly to the surveying instruments or directly to GPS-equipped machines, the money-saving potential is substantial. At present, many people are more or less doing the design a second time on-site in their projects. The only way to avoid this is to make project owners see that huge savings can be made by just spending some extra money at the start of the project; indeed, a dollar saved, is a dollar earned.

Model Behaviour

The use of drawings is changing from picking coordinates from the drawing for staking-out purposes to full representation of 3D information on utilities, buildings and road surfaces. Also, internet-based technology offers new ways to handle infrastructure projects and gives rise to whole new worlds of possibilities:

- transferring data from the office to the surveyors field computer and to the machines

- transferring as-built coordinates to the office

- checking e-mails in the field

- getting GPS-corrections to GPS-rover

- control of robotic total station

- troubleshooting of machines from the office

- monitoring machine activities.

Between every iteration of the products in the product-line we discover new and exciting ways to enhance the workflow, manageability and flexibility using the internet. We will continue to stay at the forefront, exploring new aspects of emerging technologies.

Unavoidable Change

Indeed, change is unavoidable and touches all areas of business, affects every craft, every profession and every methodology, however tested and true it may be. Change is as inevitable as it is necessary, both for positioning methods and for infrastructure projects. Innovation and evolution requires also that surveyors learn new ways of working. It is only natural for experts within any field to resist change, but this technological shift poses no professional threat. On the contrary, the possibilities are elevating the status of surveyors, since the construction process is growing increasingly dependent on the work of surveyors. Our products not only enable this technological shift but also supply the hands-on training and knowledge support that is an important key to success. Changing working methods and technology does not necessarily mean changing your personal identity.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)