The merging worlds of spatial data and construction

Digitizing workflows, improving predictability and reducing risk

After a slow, decades-long start, the digitization of construction has finally gained a firm foothold. While it is true that digital models are often used – and sometimes required – to visualize how a building will come together, true digital construction goes well beyond mere visualization. Project owners, engineers and contractors are now looking at and adopting new ways of digitizing their own workflows and finding new ways to collaborate on projects to improve predictability and reduce risk. For surveyors looking for new opportunities in construction, these changes will likely require some new approaches to satisfy the needs of increasingly sophisticated projects and players.

Spatial information plays a significant role across construction projects, from feasibility studies through design, construction, ongoing operation and then even further through retrofit, demolition and recycling. Every component of a structure has a location. Location data is paired with other layers of information such as weight, cost and source as well as the detailed geometries expected from constructible models. When combined, this information provides far more than visualization; it provides the basis for everything from detailed fabrication instructions to analytics for better project plans, improved cost controls and optimized supply chains.

The role of spatial data

Against the backdrop of all this change, surveyors can stay relevant in the construction space beyond measuring property lines, setting control on a work site and recording key assets such as utilities and topography. This traditional divide between the outside and inside roles is partly the result of some surveyors’ limited understanding of the capabilities of building information modelling (BIM), and partly the result of them underestimating the importance of their work. Although many surveyors acknowledge the value of BIM in the building process, they often mistakenly think the role of geospatial information in the context of building projects is limited to scanning, measuring and acquiring XYZ-type positioning data. In fact, their deliverables can provide exponentially more value downstream.

Beyond positioning data

As data collection becomes more efficient and sensors become more powerful, the emphasis is shifting to the office software, feature extraction and modelling automation. For those construction surveyors willing to expand their world view and their business, there is the possibility of mastering the positioning requirements of various models beyond the pure positioning data. By getting an understanding of digital construction, these surveyors can in fact better understand the end game and use that knowledge to improve on the way their work is adding to the efficiency and productivity of projects. In an economy where the more successful companies are often industry disruptors, this may be the time for surveyors to no longer ‘stay in their lane’.

Above and beyond

Moving forward, this group of surveyors can expand on their role in the construction process. However, they need to rely on themselves to push that agenda because, in many cases, architects or land developers still work with floor plans, building sections and facade elevations in 2D. They are either confined to their traditional ways of working or they simply have no immediate need for 3D or BIM deliverables because their existing customers do not ask for them. However, the market is now clearly moving in the direction of these technologies. By growing an understanding of construction technology, surveyors have the opportunity and the capability to provide higher-quality services and deliver more value to the construction value chain. For example, today’s technologies offer the possibility to capture reality in a single project management environment that supports real-time communication between multiple stakeholders. Additionally, many BIM tools feature controls that can render extremely complex models in the field, resulting in intelligent models that promote a richer understanding of the entire scenario. Surveyors can now work directly from live models, instead of staking out or listing data points. In reality, contractors are no longer looking to just get a point cloud; they want an informed answer to their question. In other words, it is the job of surveyors to interpret data rather than just deliver it, and they too can be in the position to offer contractors that richer understanding – even if they need to work with a dedicated architecture or engineering consultancy to do so.

Downstream value

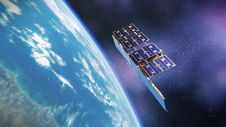

Surveyors in construction thus need to make information as intelligent and as useful as possible downstream, in the different stages of a project. Surveyors have valuable information to contribute in many of the processes in the stages before the first shovel hits the ground, such as planning, concept development, calculation, design & engineering and bidding. In those early planning stages, surveyors are traditionally tasked with putting together topographic maps and scanning site conditions, up to providing aerial photogrammetry or satellite images as part of complex, often infrastructural, projects. They can proactively provide more value with 3D visuals, illustrating the entire location in great detail, providing wider spatial awareness, documenting as-built assets and historical records. For example, having feature-rich site documentation with existing site conditions in the proposal stage allows for more efficient architectural designs, compliance with legal controls and more accurate estimates and feasibility studies.

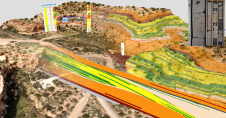

Constructible model

In the design and engineering stage, rich geospatial data generated by surveyors can help to streamline the civil design process, enabling an easier transition from a concept stage to a constructible model. By providing imaging panoramas, meshes, terrain models, utility locations (both underground and above ground) and corresponding metadata, surveyors can ensure high-quality project design. They can also help to minimize any potential rework and future requests for information (RFIs) in the construction stage in the case of discrepancies over pre-construction conditions or if surrounding assets get damaged in a later stage. Hence, a well-designed 3D model – with the right initial information provided by a surveyor – can speed up the construction process, save time and reduce waste on a job site.

Mixed reality

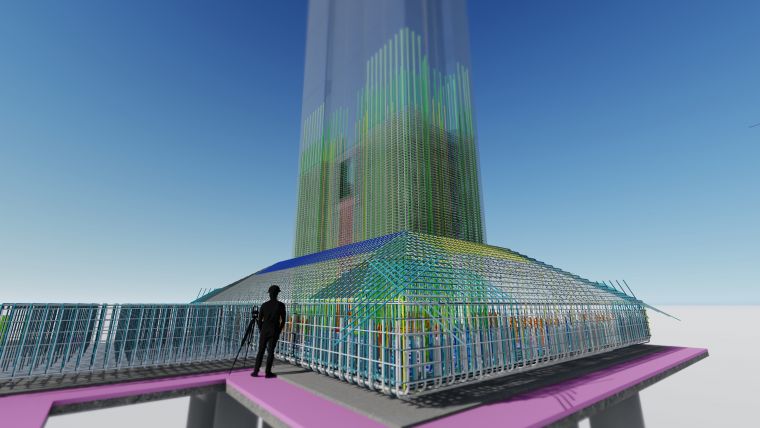

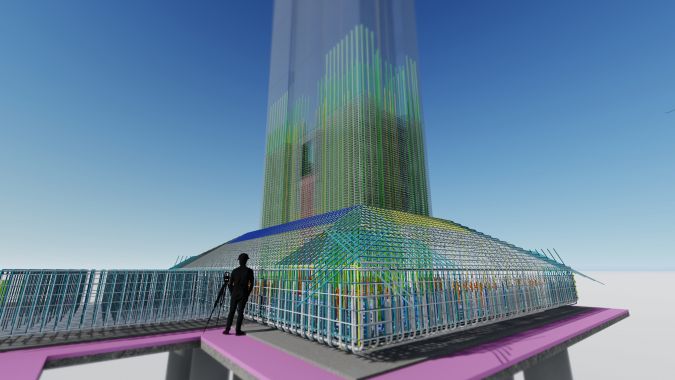

When the construction project hits the next phase, surveyors play a critical role in setting up the control network for the site, staking out the construction elements and performing the quality control, such as inspecting positional accuracies, performing verticality checks and doing real-time or campaign-based deformation monitoring. But especially in this phase, surveyors can play an essential role using BIM models in the field as a source for extracting detailed prefabrication and work drawings. In fact, there are many ways in which data from the 3D model can be accessed to provide additional insights on a job site. Over the last couple of years, the possibilities have grown from using site workstations and tablets to the latest generation of mixed-reality devices, not to mention the possibility to further enrich the 3D information with data from other sensors: GNSS, camera vision and even Lidar sensors on smartphones and tablets that enable a point map to be captured on a mobile device. So surveyors can play a major role in improving and implementing virtual and augmented reality. Mixed reality combined with laser scanners or imaging instruments can make it possible for modellers to adjust a BIM or 3D model based on just-taken scans in the field. Field connectivity and the concept of the ‘connected site’ play a major role in getting the most up-to-date designs to the field, as well as closing the loop once an element has been properly placed and verification becomes standard practice.

Cloud technology

A couple of technologies come together in reducing the time needed to place models in the physical space. First of all there is cloud connectivity, which opens models up to real-time sharing between the office and the field and between the various roles on a construction project, including that of surveyor. If they are stored on cloud platforms, project models can be accessed from several different sources, including from those tools used by other trades. A second important development is the growing availability of mobile and wearable technology that can store and load data to speed the review of modelled data on the work site. Today’s augmented and mixed-reality systems allow users to not only view but also interact with what they see on a 1:1 scale, so that they can compare components in the field against design and installation guidance. For example, Trimble’s SiteVision lets users visualize georeferenced 3D models from any angle at true-to-life scale, above or below the ground. It features the combination of a mobile device connected to a handheld centimetre-level positioning and electronic distance measurement (EDM) system. Meanwhile, the Trimble XR10 mixed-reality device combines the power of the HoloLens 2 holographic computer and head-mounted display integrated into a hard hat. Its interface lets users make natural gestures, such as clicking with fingers, pinching the screen or moving objects on the screen, to interact with designs and their affiliated data. Users can view digital models using Trimble Connect for HoloLens and can place photos and notes in the model, which can then be fed back to the office.

Operation and maintenance

In the operation/maintenance phase, stakeholders can use BIM to manage and maintain a building efficiently. For example, a 3D model integrating a surveyor’s input can be used to develop an annual maintenance plan or to quickly locate parts that require repairs. Also, any changes to installations or services in the 3D model can be simulated and calculated before applying them. The surveyor’s work is at the basis of delivering complete as-built scan and imaging documentation to the building’s owner or operator. This collection of additional metadata can be published and shared on a local intranet or website, providing additional value for facility managers, site occupants, owners or potential buyers.

Technology is making tremendous headway in connecting people and information. Surveyors, architects, designers, contractors, engineers, owners and operators are all coming to rely on this one view of reality: a model of the built environment that can deliver the information they are looking for in their role. The surveying community can play a bigger role in the lifecycle of any built asset by providing richer, more valuable and insightful information during a larger part of the building process.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)