The Surveyor 4.0

Which technical skills are needed today?

Over the centuries, all four industrial revolutions have influenced surveying instruments and the profession as a whole. This article explores which different skills and capabilities surveyors are required to develop as a result of the latest revolution: Industry 4.0.

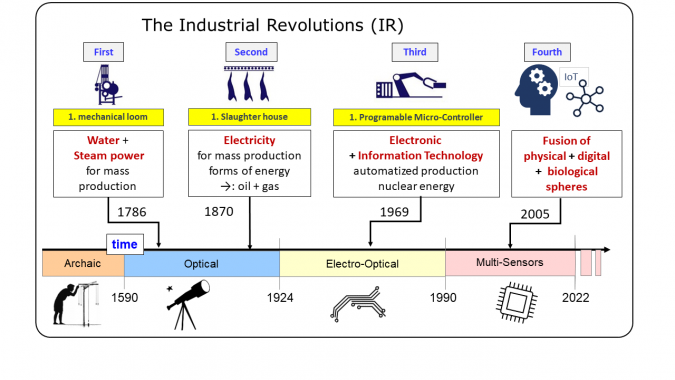

Surveying is a classical profession that goes back at least 500 years, and perhaps as many as 3,000. The technical development of surveying instruments has been very well documented over the past 400 years, and many of our classical instruments – levels and theodolites – can be traced back to the Middle Ages. Technological progress in surveying ran – and still runs – in parallel with the developments of the industrial revolutions (IRs). As the instruments and their capabilities change, surveyors are required to develop different skills in order to operate them in the field.

The main drivers of surveying in modern times are military purposes and the desire for land registration (cadastre) and objective taxation. Today’s surveyors use a variety of different measurement systems derived from the main instruments of the digital level, the electronic tacheometer (total station) and the GNSS receiver. These systems make it easier to acquire geodetic data (angles, distances, height differences and coordinates) faster and more accurately than before, provided that the surveyor has the right skillset.

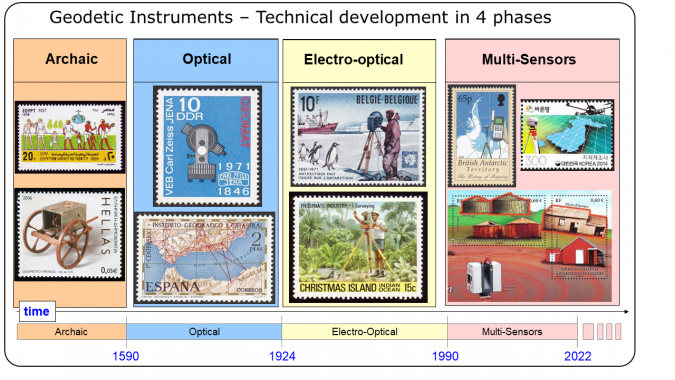

Geodetic instruments over time

The archaic phase: Few details are known about the early surveying instruments, but they are thought to have been simple in nature (e.g. the Roman groma). This phase ended in 1590 with the invention of the optical telescope.

The optical phase: During a period of more than 300 years (1590-1924), technical developments produced instruments with opto-mechanical components such as telescopes, microscopes, circles and axes, which allowed the measurement of horizontal and vertical angles. Overall, the pace of advancement was slow. The instruments did not really become handy or easy to use compared to current technology until the early 20th century. Setting up a theodolite involved about an hour of assembly and adjustment at each site before the measurement activities could begin. Then the ingenious Heinrich Wild (co-founder of WILD in Heerbrugg, Switzerland) invented the T2, an instrument that allowed surveyors to begin measuring almost immediately after setting up the theodolite. This was not only the starting point for all modern surveying instruments, but it was also the climax of the optical phase. More famous optical theodolites followed, including the WILD T3 and T4 and the KERN DKM3.

The electro-optical phase: This period was characterized by the arrival of electronic distance measurement, electronic or digital calculators, and digital storage of geodetic measurements and data. It lasted until 1989.

The multi-sensor phase: This phase took off in 1990 with the rollout of the first digital level, the first usable GPS receivers and the first one-man total station. We are still in this phase.

The impact of the 4 industrial revolutions

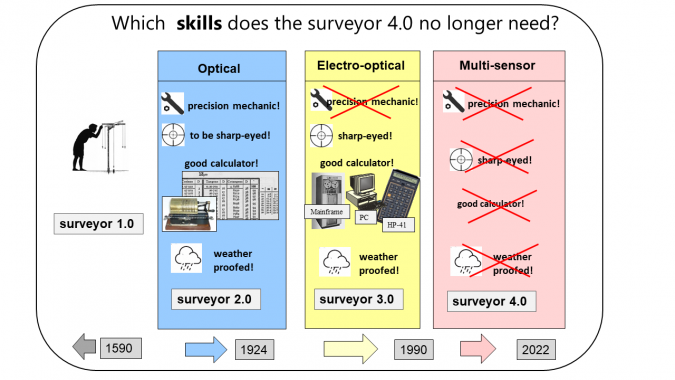

The first two industrial revolutions (Figure 2) had no significant impact on the technical progress of geodetic instruments. However, the third industrial revolution resulted in significant changes, not only to surveying instruments themselves but also to the surveyor’s whole work approach due to the arrival of electronic distance measurement (EDM), the digital storage of measurements, and digital calculators. In the subsequent decades, the development and application of software (e.g. mainframe computers and PCs) became very important and shaped an entirely new job profile for the surveyor.

The multi-sensor phase

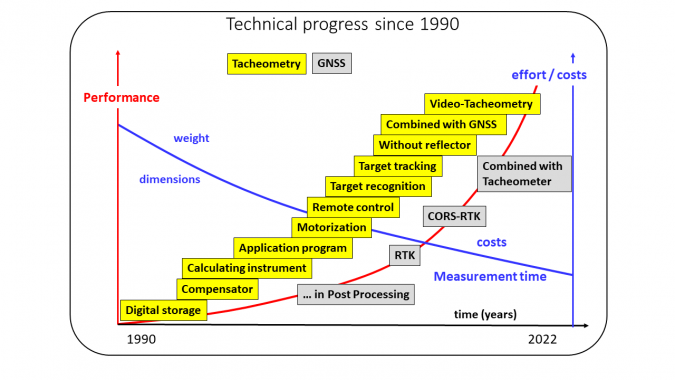

The multi-sensor phase began in 1990 with the appearance of the first digital level, the first usable GPS receivers and the first one-man station. In the early years, a technological rally took place between tacheometry and satellite-based surveying (namely, GPS). Today, this competition is over; GNSS receivers are commonly used in combination with total stations. Over the last 30 years, the industry has introduced huge technological progress to the market, and this era is still ongoing (see Figure 3).

In general, all types of instruments have become significantly more productive, more accurate and more versatile. Productivity is based on a variety of different aspects and criteria, such as the duration of a single measurement, the range of measurable distances, the number of measured distances per battery charge, as well as the skills of the operator needed for high-quality measurements. At the same time, there have been notable reductions in the amount of effort required from users thanks to instruments with a smaller size, lower weight and convenient accessories such as reflectors and tripods. Additionally, the costs have decreased in terms of not only financial investment, but also the time needed to train the operators.

The measurement process, past and present

In the past, operators of surveying instruments were called ‘observers’ because they had a direct influence on the measurements and their quality. Operators of optical levels or theodolites were sharp-eyed, weather-proofed and experienced in manual calculations. Until 100 years ago, they were also skilful mechanics. The observer read the raw observations and eliminated the influence of instrumental errors by numerous repetitions in well-defined observation schemes (e.g. double-face measurements with systematic rotation of the horizontal circle between the sets, reversed order of targets in the opposite face). Such repetitions not only reduced the number of personal errors by the observer, but also ensured effective control against blunders and calculation mistakes.

Today’s operators, rather than being observers, are users of mobile PCs with geometrical sensors. Apart from the setup of the instrument on site, they have no direct influence on the measurements. The measurement process itself is fully automatic, and the resulting values that the user accesses are the product of multiple automatic readings from one or more sensors, which are numerically compensated based on complex geometrical and physical correction models. Nowadays, 80% of the measurements in the field are executed without any redundancy because the theoretical accuracy of a single measurement by the system is sufficient, given that the measurement devices are properly working within their specifications. Users often believe that their results are true values, without any deviations. Useful checks against known values are not often carried out.

Four measurement technologies

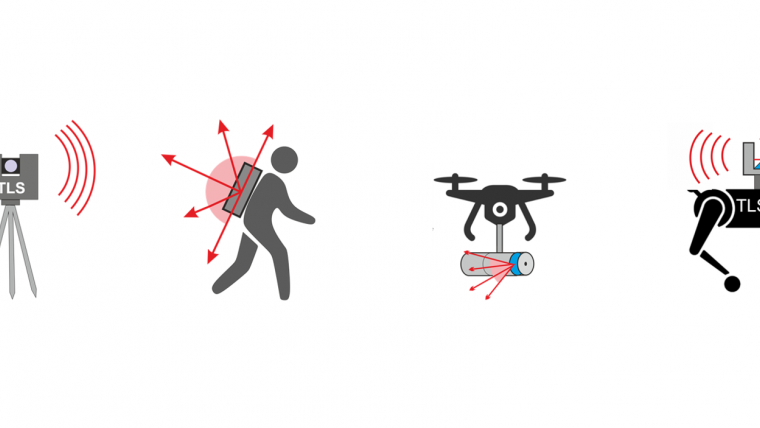

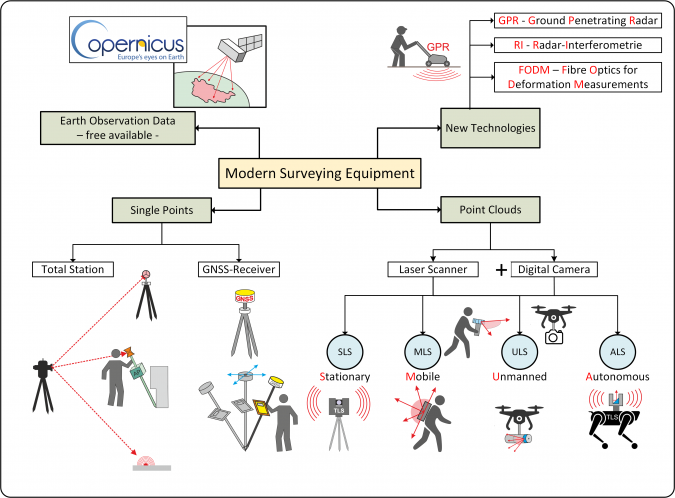

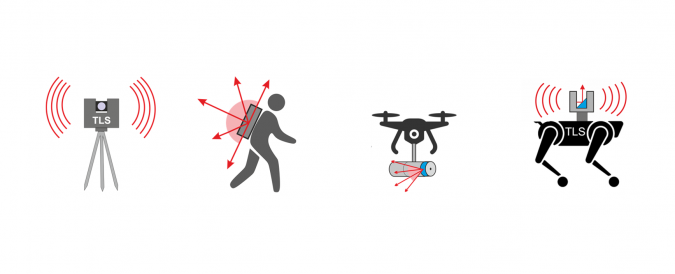

Users can nowadays choose from a rich toolbox of different measurement technologies. These can be divided into four categories (see Figure 4).

Acquisition of single points: The total station and the GNSS receiver are the main devices for capturing single points, which means that each point represents an individual geometrical object. Poles for the antennas and reflectors with integrated inertial measurement units (IMUs) make it unnecessary to set the pole precisely upright. This feature not only allows for the measurement of inaccessible points, but also offers increased accuracy and speed.

Acquisition of point clouds: Laser scanners first appeared on the market 25 years ago. They produce entire point clouds in a very short period of time. While single points have no specific meaning, subsets of the point cloud represent geometrical elements like planes, spheres and cylinders. Often combined with digital cameras today, laser scanners offer peerless productivity and versatility in the sub-categories of stationary, mobile, unmanned and autonomous laser scanning. The high measurement speed (one million points per second) opened up entirely new fields of application where traditional techniques would fail due to technological and economic limitations.

Use of new technologies: New measurement technologies have recently appeared, including ground-penetrating radar (GPR), radar interferometry (RI) and fibre optics for deformation measurements (FODM). The latter two technologies focus on the detection of small changes in the objects (deformation analysis) through repetitive measurements.

Use of freely available remote sensing data: High quality, up-to-date sets of remote sensing data are now available to everyone free of charge, such as from the Copernicus Services, following the open-source strategy of the European Union. However, these datasets require adapted analysis software approaches (big data and AI), because the smallest dataset that can be downloaded amounts to 1.6GB.

Obsolete skills

To answer the question of which skills today’s surveyors need, it is useful to start by examining which skills have become obsolete. Although there are few details about how the earliest surveyors worked, we know that Surveyors 2.0 and 3.0 were sharp-eyed, weather-proofed and experienced in manual calculations. Their calculation tools changed over time, but a lot of manual work still remained. For the Surveyor 4.0, it is now a very different story, because the measurements have become fully automatic (e.g. with automatic target finding, tracking and laser scanning). There are numerous software packages available for conducting calculations. Meanwhile, the operating time in the field has become much shorter than it was decades ago and in the case of autonomous systems it has often been reduced to almost zero.

The Surveyor 4.0

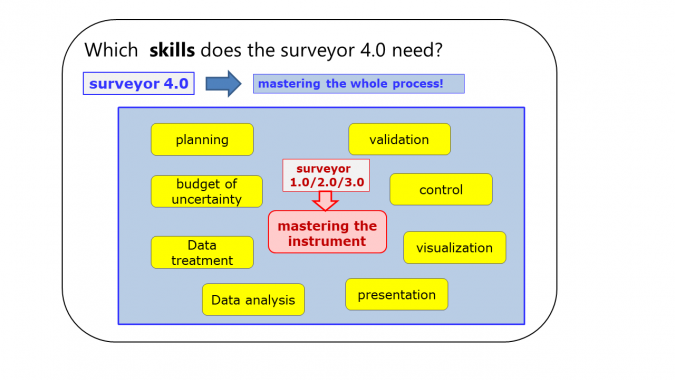

So which skills does the Surveyor 4.0 need? In order to achieve accurate and reliable data, the previous generations of surveyors spent a lot of time and effort on mastering the instrumentation.

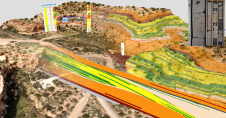

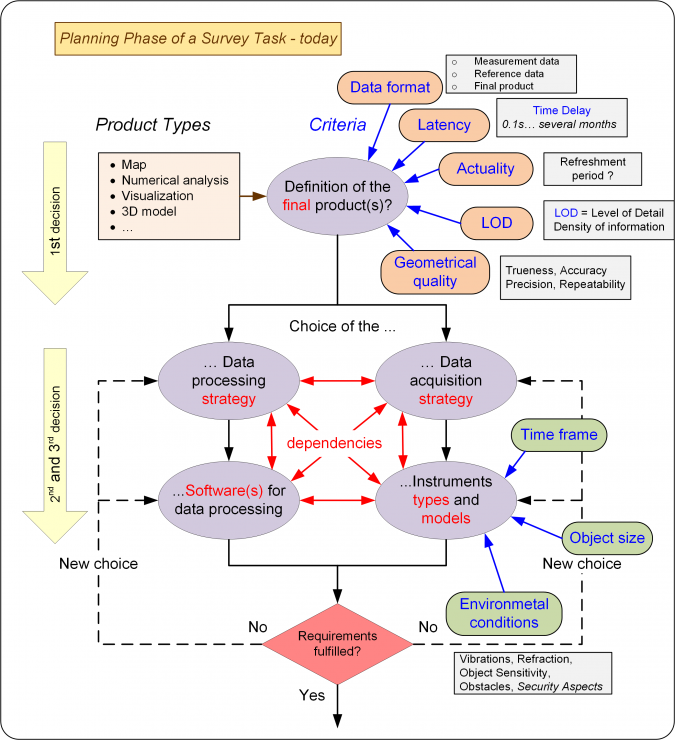

While mastering the instrumentation has become easier over the past years, today’s surveyors now have to master not only the instrumentation itself but also the whole process, from the acquisition, treatment and analysis of the data to the visualization and validation of the final result (see Figure 6).

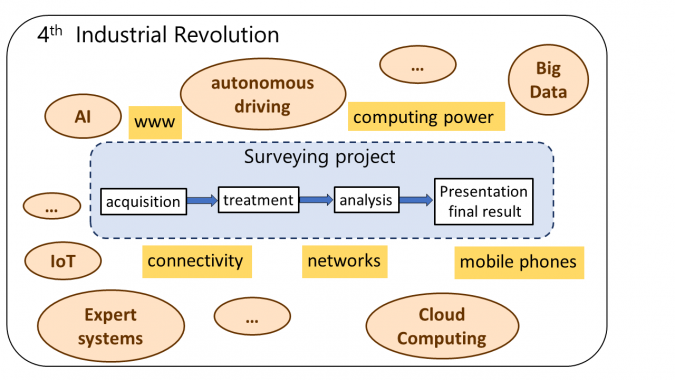

Moreover, what is the impact of the internet, ubiquitous connectivity and computing power that are driving the fourth industrial revolution? It is safe to say that the modern surveyor is already using significant parts of technologies such as AI, big data, IoT, expert systems and cloud computing.

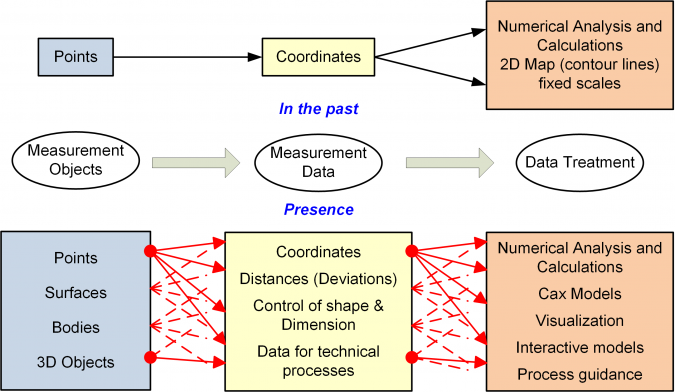

In the past, surveying decisions were relatively simple. There were only a few measurement methods and, in contrast to the current situation, there was no need to choose between different types of instruments because there was a specific instrument for each task. In general, the execution of all data acquisition was guided and controlled by regulations, and there was no room for individual decisions regarding the measurement procedure. The measurements determined only points – in the horizontal positions or heights – and the final results were either a map of predetermined fixed scale or a numerical analysis (Figure 9).

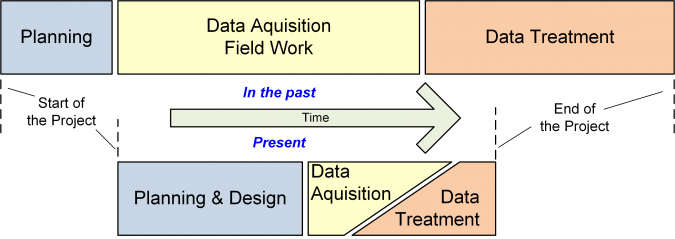

Today, both the possibilities and the actual demands are wider and more varied. A surveying project can be divided roughly into three phases: planning & design, data acquisition, and data treatment (Figure 10). In former times they were executed consecutively. Nowadays, however, the execution phase is preceded by a much longer planning phase, and the first part of the data treatment runs in parallel with the data acquisition phase. Due to the far more efficient equipment used for data acquisition and treatment, a project can be finished much faster than in the past. At the same time, the results can be used for a greater variety of purposes, such as planning, mapping at different scales and with different levels of detail, volume determination, and so on.

This has transformed the Surveyor 4.0 from a skilled observer into a project manager, creating and producing geodata. At the start of each project, the surveyor needs to define the task, including the type and shape of the final result. Each subsequent step, from the data acquisition to the final result, must then be determined. For the best data acquisition strategy, the Surveyor 4.0 needs to know all about the technical restrictions (e.g. if it is only possible to perform measurements at night time) and the relevant safety regulations, not to mention the economic aspects of the project.

Once a data acquisition concept is established, the Surveyor 4.0 needs to check whether the measurements goals (e.g. accuracy, point density, acquisition speed, required distances between the sensors and the objects) can be achieved. In addition, they are recommended to validate the acquired data.

Summary of skills

The skills required by the Surveyor 4.0 to meet the current needs can be summarized as follows:

- Measurement technologies: Thorough knowledge of all the potential measurement systems and technologies, including their limitations and restrictions (both legal and technical), is necessary in order to optimally choose the acquisition and data treatment strategy. Knowledge about the quality of the data and the specific output formats is also required.

- Mathematics: In particular, mathematical knowledge should cover geometry, statistics, least squares adjustment and blunder detection.

- Business administration: To include a comparative cost calculation between the different measurement options in the decision process, knowledge and experience related to calculating costs is needed.

- Programming: A project often calls for the surveyor to filter, select, transfer or manipulate the acquired or processed data. Therefore, programming capabilities in appropriate programming languages are required.

- Soft skills: The success of a surveying project depends on a close and constructive partnership between the surveyor and the customer, especially during the planning phase. This is supported by soft skills such as communication skills, presentation skills and teamwork.

Conclusion

The unique selling point of surveyors has always been their ability to acquire precise and detailed geometrical information about large objects, whether natural or artificial. This has not changed over the last century. However, the surveyor of today has become a versatile producer and manager of precise geometrical data. Whereas in the past it was the only task, mastering the instrument is nowadays reduced to just one task out of many.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)