Rapid advancements and improvements in technology have made a huge difference to surveying techniques and solutions. Such a densely populated market of devices can feel overwhelming, leaving buyers baffled as to what is the best option for them. Here, Andrei Șueran from GRAPHEIN draws on his own experience to help fellow professionals make these challenging choices. Having put various technologies to the test during a project in Romania, he compares both the results and the amount of effort required.

About GRAPHEIN

Nine years ago, when Andrei Șueran and Eugen Ursu – his business partner – were at a crossroads in their careers, they decided to take the next step and build their own company: GRAPHEIN. To say it was challenging would be an understatement. Opening any business is a hard thing to do, but especially when the aim is to introduce new technologies and solutions to a market that is very set in its ways. It was a gamble, but luckily GRAPHEIN came out winning.

A particular source of pride for both business partners is that they have managed to gather people in their company who not only deliver impressive results – no matter the project – but who are also very open and passionate individuals who are attentive to colleagues and customers alike. Today, GRAPHEIN is a service integrator for the construction industry – engineering surveying, 3D scanning & modelling and building behaviour monitoring – and Autodesk partner. The company has recently put together a research & development department. After expanding in key cities in Romania, the next step will be to work towards growing abroad.

In Romania’s landscape, it is not uncommon to come across beautiful buildings left abandoned or decaying – pieces of history bearing witness to the influence of other nationalities. Architecture enthusiasts, city lovers and other visionary people dream of breathing new life into these buildings as they recognize how much they could contribute to growing and nurturing local communities.

One example is The Small Trianon, which is under the care of the people from the ‘Florești Domain’ foundation. Built in the early 1900s, it was intended as a gift from Gheorghe Grigore Cantacuzino, a Romanian politician and former prime minister, to his granddaughter Alice. Inspired by the Petit Trianon of Versailles, the edifice has been through a lot, including being converted into a tuberculosis sanatorium and, during the communist regime, being taken by the state as a result of nationalization. It has also witnessed both World Wars, suffering damage by both Germans and Russians, and has stood through Romania’s two most devastating earthquakes. But all this is in the past, and the future now looks bright for The Small Trianon. There are plans to turn it into a hotspot for festivals, camping and conferences, with some events already having taken place there.

Assessing the level of degradation

Before the restoration process started, the client wanted to understand just how damaged the building was. In 2020, GRAPHEIN helped the client with this complex task by making a 3D model of the site using photogrammetry. This enabled them to gain valuable insight into the state of the building and how they could get it back into shape. Since a lot has changed in terms of surveying technology since then, in 2023 the GRAPHEIN experts revisited the site with different technology – this time, oblique photogrammetry and Lidar scanning – in order to compare the results and the amount of effort required.

Photogrammetry

In order to accomplish the mission of helping the client to understand the state of the building, it was necessary to conduct a comprehensive study of degradation. This is where the first choice in terms of technology had to be made. Although the terrestrial laser scanning route could have been a possibility, GRAPHEIN chose to conduct the survey using the DJI Phantom 4 equipped with the TOPODRONE PPK system. Photogrammetry was identified as producing a more precise, more visual result that would therefore be much more insightful and useful. Additionally, besides requiring a high-quality and detailed result, the client had asked for fast delivery within a maximum of three days. Photogrammetry was the most viable solution for meeting those requests. In terms of on-the-spot effort, three flights were needed, each lasting about 20 minutes. Summing up the benefits, photogrammetry achieves top-notch results in a minimum amount of time.

Oblique photogrammetry and Lidar scanning

As part of the company’s field research, GRAPHEIN revisited the site in 2023, but this time with different photogrammetry equipment and also to conduct a Lidar survey.

In order to achieve oblique photogrammetry, the Autel EVOII was used with the TOPODRONE PPK module. To generate the new point cloud, the company relied on the DJI Matrice 300 RTK with a TOPODRONE P61 camera. As additional research, the latest release – the TOPODRONE 200+ Lidar – was also put to the test.

In terms of the amount of effort, once again three flights were conducted:

- Autel EVOII was employed for oblique photogrammetry. The 25-minute flight resulted in approximately 767 images. It took two hours to process these in Agisoft Metashape Pro as the basis for the 3D model.

- Matrice 300 and P61 were employed for photogrammetry. The 20-minute flight resulted in 331 images. The processing took 90 minutes using the same software as above.

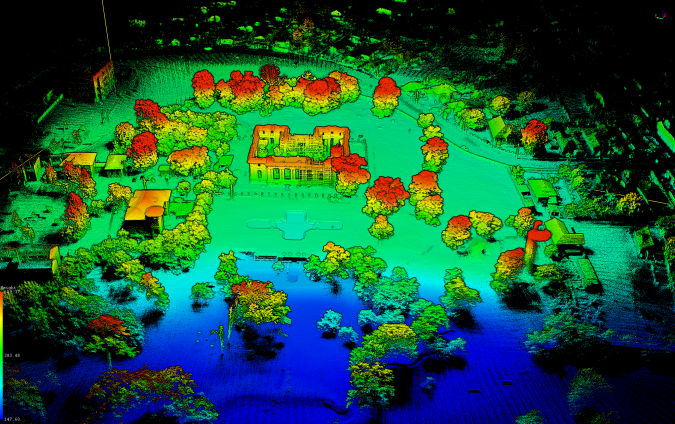

- Matrice 300 and LiDAR 200+ were employed for scanning. The flight was completed in under six minutes, and only an hour was needed for processing. The point cloud contained 39,891,629 points.

Comparison of the results

Comparing the results of the two photogrammetry surveys shows that the oblique mapping survey resulted in a better model of the site. However, the orthophotos came close in terms of quality. The only difference is that the colouring was better with Autel EVOII. Using the TOPODRONE P61 camera produced a better 3D model since obviously the 61mpx sensor is able to capture in better detail than the 20mpx sensor.

This study also revealed how remarkably Lidar technology has evolved. The version employed by GRAPHEIN proved satisfactory in every field of interest, having a better Epson IMU than its predecessor and a better-calibrated laser head. Not only is the point cloud of higher quality, providing an increased point density which drastically reduced the noise, but it was also able to capture more aligned points than the previously used solution.

Conclusion

From a precision point of view, the different photogrammetry solutions – when used alongside a PPK system – produced nearly identical results. However, there is a clear difference when the camera sensor has a better resolution, as in this case. Above all, GRAPHEIN’s research in this project demonstrates that the most insightful results can be achieved by combining the two aforementioned techniques and products. This obtains high-quality and richly detailed, coloured point clouds, backed up by orthophotos.