Calibrating Survey Instruments

A Modern Calibration Bench

The geomatics profession is implicated in several ISO standards. The important ISO9001: 2000 prescribes regular instrument testing and calibration. To help meet required stringent alignment tolerances, a modern calibration bench has been developed for the calibration of survey instruments under internationally recognised COFRAC accreditation.

Surveyors must as professionals fulfil certain legal, regulatory and/or accuracy requirements for their clients. They will typically strive to do so in an optimally cost-effective way and with the most appropriate equipment for the job at hand. This naturally requires good understanding of and confidence in the instrumentation employed. Clients want the most from what they pay for. Legislative authorities and private and public companies require assurance that the services rendered conform to globally accepted rules of best practice. Today, however, the rapidity and simplicity of modern survey instruments result in a tendency to assume measurements are exempt from error. This is, of course, simply not true. Instrument verification, testing and calibration are every bit as important today as they were in the past.

Standards

Few people question that their bankcard is working when they make a withdrawal from a machine. This confidence would not be possible, however, without standards. While driving we stop at hexagonal, not round or square stop signs. These are just two of the thousands of standards that impact on our everyday lives. A standard is a rule or requirement determined by user consensus and prescribes the accepted and (theoretically) the best criteria for a product, process, test or procedure. The benefits of a standard are safety, quality, interchange–ability of parts or systems and consistency across international borders. The International Organization for Standardization (ISO), a global network that identifies and delivers international standards required by business, government and society, is the world’s leading developer of international standards.

ISO and Surveying

Several ISO standards are applicable to the geomatics profession: ISO 191xx series through TC 211, ISO 12858, ISO 17123 and ISO 9000. Among these, the ISO 9000 family is primarily concerned with quality management and represents an international consensus on good management practices aimed at ensuring a business or organisation consistently delivers products or services that meet the customer’s quality and regulatory requirements. These good practices have been distilled into a set of standardised requirements for a quality management system, regardless of type of organisation. An ISO 9001: 2000 certification is considered proof of a supplier’s capability to design, manufacture and supply products and services that conform qua quality. One rule in the ISO 9001: 2000 standard concerns the control of monitoring and measuring devices. It requires that, to ensure valid results, measuring equipment shall be calibrated or verified against international or national measurement standards at specified intervals or prior to use. Where no such standards exist, the basis for calibration or verification shall be recorded. Every instrument is unique, having its own specific characteristics that may evolve in response to internal and external factors. Each characteristic must be well-known and controlled to guarantee optimal performance. In addition, manufacturer-stated instrument accuracy may only be achieved using calibrated instruments operated in accordance with their instruction manual. With modern push-button, black-box instrumentation, user-friendly software and self-calibrating systems, it is easy to be lulled into complacency. In reality, no instrument is error-free and therefore surveyors must periodically check and calibrate equipment.

Accredited Laboratory

ISO 17123 provides a set of procedures that can be used to test survey equipment. In addition, the Fédération Internationale des Géomètres (FIG) Recommended Procedures for Routine Checks of Electro-Optical Distance Meters (EDMs) outlines appropriate procedures relating to EDM testing. Field tests should not be confused with the calibration of an instrument. Calibration links the instrument directly to international standards and is the act of checking or adjusting by comparison with a standard or reference the accuracy of a measuring instrument. An example of a standard is a calibrated laser interferometer, which measures distances (relative displacements) more accurately than an EDM. A calibration is performed at a laboratory which has been awarded accreditation by an internationally recognised organisation such as the French Committee of Accreditation (COFRAC), the UK Accreditation Service (UKAS) or the Standards Council of Canada (SCC). An accredited laboratory follows the ISO/CEI 17025 standard: General Requirements for the Competence of Testing and Calibration Laboratories. Best practice recommends that equipment-functioning tests should be made on a daily basis. The repeatability of an EDM instrument should be verified weekly using known distances at a home test-field. Detailed investigation may be carried out less frequently, but at not less than three-monthly intervals. Calibration is generally performed less often than field tests and may be conducted if there is suspicion of results issuing from an instrument in use or after repair. One important reason for calibration is to improve precision by applying a calibration model to measurements.

Instrument Error

Common sources of error are the operator, the instrument and the atmosphere. There are four main EDM instrument errors: zero error (index error, constant error), scale error, cyclic error (bias error) and pointing error. Pointing errors should be adjusted for optimal instrument performance. Similarly, scale errors due to modulation frequency variation should be generally calibrated and/or adjusted using a calibrated frequency meter. The de facto standard for zero and cyclic error calibration closely resembles the ISO 17123–4 standard. The laser-tracker distance meter calibration procedure is outlined in the American standard ASME B89.4.19 (2006), the German standard VDI 2617 Part 10, and currently under the ISO 10360 standard. These calibrations are typically performed on a calibration bench such as those located at the European Organization for Nuclear Research (CERN) in Switzerland, the Stanford Linear Accelerator Center (SLAC) in the US and the European Synchrotron Radiation Facility (ESRF) in France. The latter, which has internationally recognised COFRAC accreditation for the calibration of EDM and laser-tracker distance meters, is a joint facility supported and shared by seventeen European countries and operates the most powerful synchrotron radiation light source in Europe. Light sources are accelerator-based machines that produce exceptionally intense, tightly focused beams of light in the energy range from infrared to x-rays. They are used in fields such as physics, chemistry, materials science, biology, medicine and forensics. Alignment is of crucial importance for correct working of the ESRF. Alignment tolerances are typically less than one millimetre and often of the order of several micrometres.

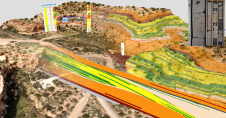

ESRF Calibration

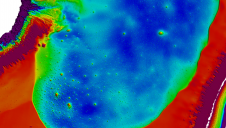

To help meet extreme tolerance requirements the ESRF has an active programme concerned with all aspects of survey instrument calibration aimed at improving instrument performance. If an instrument has a systematic or repeatable error that can be modelled the error can be corrected and the measurement results improved. An interferometer is installed on a fixed pillar at one end and the instrument to be measured (EDM or laser tracker) is installed on a fixed pillar or heavy tripod at the other end. Interferometer and instrument reflector are both installed on a servo-controlled carriage. The bench is equipped with an accredited meteorological station that measures temperature, pressure and humidity. Additional temperature sensors are installed at regular intervals along the bench to improve corrections for variations in refraction along the line of sight. A typical calibration comprises determination of index error, followed by determination of cyclic error by comparing measured distance displacements with accredited laser interferometer. Distances are measured by moving the servo carriage at 10-cm intervals along the bench. The calibration curve obtained can be modelled to considerably improve field measurements. At the ESRF, the enlarged uncertainty for these calibrations is 0.17mm for a 2-50m EDM calibration with instrument resolution of 0.1mm, and 0.05mm for a 0.3-50m laser-tracker distance meter calibration.

Acknowledgements

Thank you to Gilles Gatta, Bruno Perret, Christophe Lefevre and Laurent Maleval, without whom the ESRF calibration bench would not work.

Further Reading

Martin, D. and Gatta, G., 2006, Calibration of Total Stations Instruments at the ESRF, in Proceedings of the XXIII FIG Congress in Munich, Germany, 8-13 October 2006.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)