Dam Fine Data: Sub-millimetre-resolution UAS Dam Surveys

In early 2021, the Orthodrone team crowded itself and its equipment into a tiny Swiss gondola and made its way to one of two dams scheduled for water-side inspection – no easy feat, given the metres of snow closing off many alpine roads during the winter. Often situated in difficult-to-reach locations, Swiss pumped storage plants can greatly benefit from sub-millimetre-resolution uncrewed aerial system (UAS) dam surveys. With the appropriate survey-grade, metric sensors, current UAS can offer safer access and increased cost-effectiveness compared with more traditional inspection methods, while providing comparable or better data.

Much more than chocolate, knives and clocks: Swiss hydropower

Well over half of the energy produced in Switzerland comes from hydropower, and Axpo Holding AG is Switzerland’s largest hydropower producer. The canton of Graubünden, where this project took place, contributes over 20% of the electricity generated from hydropower in the country, totalling more than 7.9 billion kilowatt hours per year.

Most of the hydropower in Switzerland comes from storage power plants and run-of-river plants, with only 4.3% of Swiss hydropower provided by pumped storage hydropower plants. However, pumped storage plants are an important component of a hydropower system, helping to balance supply and demand. In a pumped storage system, reservoir water is sent through pressure pipes to drive turbines that generate electricity to be fed into the power grid. In addition to providing energy during peak usage, pumped storage plants also allow for the conversion of excess electricity from the grid through the transfer of water from the lower reservoir to the higher reservoir during off-peak periods. This makes them a vital resource for smoothing energy consumption. Traditionally, water-side inspections of the dams have caused significant turbine downtime.

Swiss dam safety: An internationally recognized regulatory system

Throughout the lifetime of a dam, appropriate operation and consistent maintenance are essential for minimizing risk. Regular inspection helps to ensure the safety and continued operation of a dam, an area in which Switzerland – highly praised by the International Commission on Large Dams – has excelled, having had no dam failures since 1887. However, conventional dam inspections require resource-intensive data collection by means of workers atop platforms suspended from the dam, providing a prime use case for UAS dam surveys to improve inspection safety and efficiency.

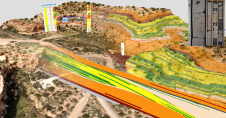

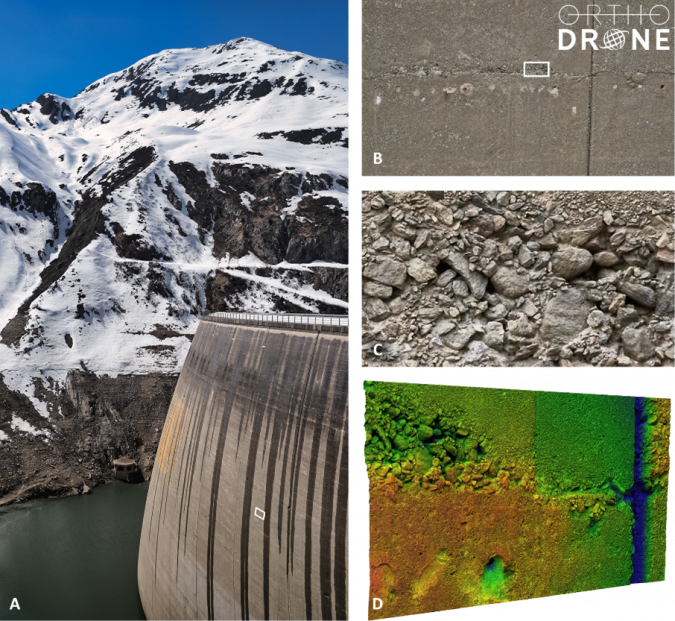

Unlike popular consumer-grade drones, Orthodrone’s equipment includes made-to-measure UAS and metric cameras, made specifically for surveying and inspection. Phase One’s iXM100 is its favourite tool for photogrammetric data acquisition, allowing the Orthodrone team to get the sub-millimetre-resolution data required for a detailed analysis of the safety of a dam. Compared to cameras such as the DJI Zenmuse P1, the iXM100 not only has superior image quality, but also a faster trigger: within the typical two-second trigger interval for a single shot of the DJI P1, the iXM captures six images – requiring less flight time to capture the necessary data.

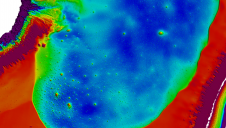

With the current setup, the team can achieve a 1.5mm ground sampling distance (GSD), with a footprint larger than 17 x 13m, hovering at about 32m or 60m from the dam face (depending on the lens). A 1mm GSD (footprint roughly 12 x 9m) is possible at a distance of up to ~40m, whereas a 0.5mm GSD (footprint roughly 6 x 4.5m) can be attained up to ~20m from the dam wall.

Complete control for sharper images

While utilizing a cutting-edge industrial camera considerably enhances productivity, added automation eases the job. All of our UAS are equipped with real-time kinematic GNSS, Lidar-based rangefinders and complete camera setting control, simplifying not only post-processing, but also allowing for sharper images with spot-on focus.

This is particularly important due to the convex shape of most dams, which poses challenges for pilots and their spotters, especially during water-side dam surveys in gusty winds. Of the two dams we surveyed, one was 127m high with a crest length of 480m, and the other was 117m high with a crest length of 560m. Such areas also require terabytes of data storage for the desired sub-millimetre resolution of the images, making them a prime use case for our onboard processing units with significantly larger data storage.

Deliverables – It’s all about perspective

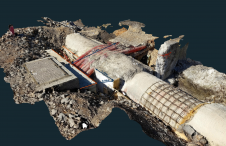

With the gathered images and derived multidimensional deliverables, dam managers can assess the dam face for abnormalities or degradation. High-quality data is essential for a thorough assessment of structural integrity, and even the most miniscule cracks can be detected by sub-millimetre-resolution UAS dam surveying. This enables inspectors to identify areas of concern, which are then properly addressed to mitigate risks before they can turn into more costly and potentially more dangerous issues.

Orthodrone is currently working on the development of a new, fully offshore capable, gas-hybrid multi-rotor UAS, which can combine two iXM100 cameras and a survey-grade Riegl Lidar while keeping the entire payload completely stable. Stability is paramount for flying in offshore conditions (or in this case, windy alpine valleys). High wind tolerance will make aborted missions due to high winds a thing of the past. The new system will also be able to carry a single, large focal length lens, enabling inspections at half-millimetre resolution from a distance of 40 metres, allowing for a new level of risk management while gathering the best possible data from afar.

About Orthodrone

Orthodrone is your reliable partner for drone-based critical infrastructure inspections – including sub-millimetre photogrammetric dam surveys in hard-to-reach areas. With hours of hover time and top-of-the-line sensors, Orthodrone is revolutionizing the way we gather, process and utilize spatial data. For a closer look at one of these dams, follow the link below to see the point cloud.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)