Revolution in Highway Surveying

Using StreetMapper 360 in the Netherlands

It's a familiar sight: roads are closed due to road works and surveyors doing road measurements. Besides causing traffic delays, these surveys are costly - traffic has to be managed and employees brought in to work night shifts. Add to this the pressure to deliver new designs as quickly as possible, and the impact this has on accuracy down the line. Now, Dutch surveying specialist Geomaat has completed pre-construction surveys without the need for road closures by using the StreetMapper 360 system from 3D Laser Mapping. The measurements were taken with sub-centimetre accuracy while travelling at normal traffic speeds.

View Larger Map

High-speed laser mapping by StreetMapper is revolutionising highway surveying in The Netherlands. StreetMapper 360, the world's most accurate mobile laser mapping system, was developed by 3D Laser Mapping in conjunction with German guidance and navigation specialist IGI. The system employs the latest laser scanning technology for improved field performance, accuracy and precision navigation, including a solution for reduced GPS coverage in urban areas. This advanced technology is combined with a flexible, modular configuration and ease of use and deployment (see Figure 2).

Rapid Mapping

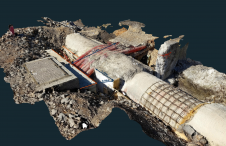

StreetMapper 360 has been specifically designed for the rapid 3D mapping of highways, runways, railways, infrastructure and buildings. Vehicle-mounted lasers are used to provide a 360-degree field of view with high-precision mapping to a range of 300m. Capturing every detail along the highway corridor, including barriers, gullies and overhead wires, surveyors can create highly accurate 3D computer models for planning, maintenance, wide load route assessment and post-incident investigations.

A32 Project

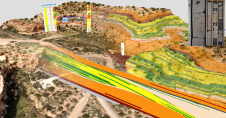

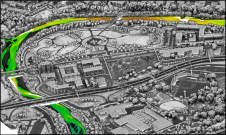

Geomaat purchased the StreetMapper system last year following rigorous field trials. The latest survey was for reconstruction of the A32 highway between Heerenveen and Steenwijk in the northern part of The Netherlands (see Figure 1). Built about ten years ago, using asphalt slag as the foundation, the road had subsequently degraded due to a chemical reaction. This resulted in large strokes (holes and gaps) requiring remedial attention, which in turn was dependent on a highly accurate survey of the highway.

In the past, the road would have been closed for several successive nights for every ten kilometres of highway and would be manually surveyed in order to produce a new design for use by the Dutch road administration Rijkswaterstaat, to ensure compliance with all applicable standards, and by the construction company to calculate the volume of asphalt required. Due to the expense of traffic management and other contributing factors, pressure is always applied to complete the survey as quickly as possible and to process the survey measurements and deliver a new design in a shorter time period. This may result in poor survey data, inaccuracies introduced during processing and failure to properly check the resulting design.

Survey Revolution

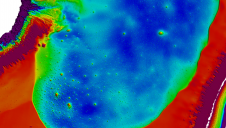

Using StreetMapper, Geomaat revolutionised the survey element of the project. The pre-construction survey was completed two months before construction began, without the need for road closures and with minimal impact on other road users. The point cloud data collected by StreetMapper was processed to match the Dutch coordinate system. A comparison with manually surveyed points along the highway showed an average difference of 5mm and a standard deviation of 8mm. The StreetMapper data was then used to prepare a new road design, accurately replicating existing features, such as road camber, and matched to fixed structures such as bridges (see

Figure 3). Geomaat specialists were able to create a whole new 3D model of the new road, leading to the obvious advantage of bringing the model to the working parties long before the start of the road works. The digital model was then used by the construction company to calculate the volume of materials required to re-lay the road surface using a grading machine controlled by GPS and lasers.

Geomaat sees obvious advantages of the StreetMapper 360 system over traditional survey techniques. It has improved conditions for the survey team, reduced impact on other road users and, importantly, more importantly, reduced costs. By using StreetMapper on this project savings of up to 50% were achieved. Considering the accuracy of the system is, its use for highway projects should be mandatory.

Future Developments

Since rebuilding the road surface of the A32, Geomaat used the StreetMapper 360 in mapping over 200km of highway for Rijkswaterstaat. The gained data were used to measure the height of bridges and road signs for updating the GIS road maps of Rijkswaterstaat (see Figure 4). StreetMapper 360 continues to prove itself in real world projects across the globe: about 2000km of highway were scanned in Sweden to provide data for planned maintenance work; it helped with the redesign of a highway intersection as part of a 120 million pounds regen-eration project in the UK, as part of a futuristic project to advance mobile mapping in Ireland, and it was used to survey a prestigious international sporting venue in the US.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)