Printhead

Whilst our lives have been drastically altered by computers and high-resolution screens, we still want to read text and view graphics and images on paper. The paperless office has proved an illusion. So how do printers work? How do they spray ink onto paper? The ink-spraying component is called the “printhead”. A printhead: I know what it is, I know what it does, but how does it work??

The first printers employed “dot matrix” technology. Fifteen pins grouped 3x5 in a matrix slowly and noisily hammered the ink out of a carbon tape. The result was sometimes hard to read. Back in the 1970s, finding a reasonably priced alternative to dot-matrix printing was a major R&D goal. The answer came at the end of the decade: thermal inkjet technology. The printhead consists of nozzles grouped in a matrix, as were the pins in a dot-matrix printer, and the nozzles extract ink from a cartridge and eject it onto the paper. A heater heats the ink in the nozzle until a vapour bubble is formed and a drop is shot onto the paper under pressure. The more nozzles, the faster the ink can be fired onto the page, the faster the print speed and the more bubbles may be sprayed onto a square inch, resulting in high image quality. In 1984 printheads consisted of twelve nozzles, now there are 3,900. Nozzles in a modern printer can each fire up to 36,000 bubbles per second, and 3,900 nozzles give over a billion printhead drops per second.

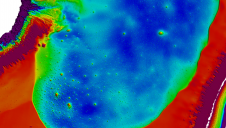

Image Quality

Printer resolution, expressed as Dots Per Inch (DPI), depends on the number of nozzles, how accurately they are positioned and how the bubbles are ejected. As the bubble falls on the paper it splits into a primary and a secondary drop, the latter supposed to fall on the primary. But air may disseminate the drops, causing either a tail or a satellite. The higher the print speed the more satellites are created. Paper type is another essential determining parameter in print quality.

Moore’s Law

Printheads consist of many small parts. The tiniest deviation in welding or gluing during the manufacturing process may result in malfunction or affect the lifespan of the device. Vibration - always present - and rapid temperature change in the head may also cause damage. In 2005, after five years of R&D, Hewlett-Packard succeeded in developing a fully integrated printhead manufactured as a single, aligned unit using a new “photolithographic” fabrication method that squeezed 3,900 nozzles onto a single print head. Because this technology allowed ink to be sprayed faster and in higher quantities than previously the paper had too little time to absorb the ink, so that new ink and paper types had to be developed. Up to now the development of inkjet technology has obeyed Moore’s Law, the number of nozzles on printheads doubling nearly every two years (Figure 5). Photolithographic production techniques will help perpetuate this pattern for at least another decade. In a few years’ time we will be wondering why only 3,900 nozzles?

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)