Surveying and Monitoring Systems Ensure Safety on Record-breaking Alpine Tunnel

This article was originally published in Geomatics World.

The world’s longest and deepest rail tunnel under the Alps has been completed to line and level thanks to Swiss measurement and monitoring technology.

On 1st June 2016 the 57km twin-bore Gotthard base tunnel was inaugurated with full service expected to begin in December 2016. The tunnel, which is the longest rail tunnel in the world, will provide a high-speed rail link under the Swiss Alps between northern and southern Europe. The previous longest tunnel was the Seiken in Japan at 53.9km, which beat Eurotunnel’s 50.5km.

The Gotthard tunnel’s inauguration was marked by an odd opening ceremony featuring dancers and a partially naked woman decked out as a bird with great white wings hovering above actors dressed as tunnel workers, apparently to honour the nine men killed during construction.

Surveying and monitoring systems made the construction of the Gotthard Base Tunnel possible. The tunnel comprises a total of 151.84km of tunnels, shafts and passages, it is the world’s deepest traffic tunnel and the first flat, low-level route through the Alps.

The main purpose of the tunnel is to increase local transport capacity through the Alpsr, especially for freight, notably on the Rotterdam–Basel– Genoa corridor, and more particularly to shift freight from trucks to trains. This not only significantly reduces the danger of fatal road crashes involving trucks, but also reduces the environmental damage caused by the ever-increasing amount of freight hauled by heavy trucks. The tunnel will provide a faster connection between the Canton of Ticino and the rest of Switzerland, as well as between northern and southern Europe, cutting the Zürich–Lugano–Milan journey time for passenger trains by one hour (and from Lucerne to Bellinzona by 45 minutes).

The breakthrough, which was achieved six years ago on 15 October 2010 was made possible by highly precise surveying and monitoring technology supplied by Leica Geosystems.

Boring the tunnel started from both sides of the mountains and met in the middle with barely any deviation; it was a truly challenging task. Highly precise measuring instruments were needed to successfully accomplish the project.

Measuring Down to Millimetre Accuracy

At the tunnelling site, the surveying consortium VI-GBT began measuring in 1996, when construction work began 20 years ago. The surveying engineers set up a basic network with 20 reference points. For this task, they used total stations and GNSS solutions from Leica Geosystems.

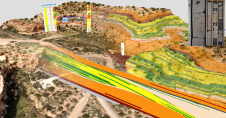

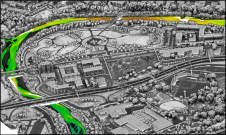

The tunnelling began at Erstfeld (north portal) and Bodio (south portal), but also at three intermediary points where side channels joined the main tunnel: Amsteg, Sedrun and Faido. In Sedrun (1,405 m high), a vertical tunnel 800 m long was drilled down to the main tunnel so construction workers could push north as well as south from that point.

During tunnel construction, surveying and measuring tasks had to be repeated every 400 metres. In order to make sure the tunnel was on course, the surveyors had to check coordinates of the reference points. In addition, the exact height had to be measured with levelling devices, also from Leica.

Breakthrough

“When we broke through in the middle of the tunnel on October 15, 2010, the two tunnel sections met with a deviation of only 8 centimetres or 3.1 inches, whereas 25 centimetres would have been tolerated,” said Ivo Schaetti, a surveying engineer of VI-GBT. He explains that surveying tunnels is very demanding due to temperature changes, humidity and dust. “Thankfully, we could always rely on the accuracy of the surveying solutions from Leica Geosystems,” Schaetti adds. “They are very precise. You can measure a distance of 400 metres with an accuracy of less than a millimetre or 0.03 inches.”

Monitoring the Dams Above the Tunnel

During the entire construction period, the surrounding land of three artificial lakes above the tunnel required monitoring: Curnera, Nalps and St Maria. There was a slight probability that the construction of the tunnel – 1.4 kilometres beneath the lakes – could affect the stability of their dams. This monitoring was also done with Leica instruments using fully automated devices throughout the entire tunnel construction from 2000 until 2015.

“Our total stations monitored the tiniest movement of the prisms that were mounted near the dams,” says Falko Henning, Leica Geosystems product manager. “Happily, no unusual movements occurred.” There was no major delay during construction time, and the tunnel will be inaugurated as planned.

This article was published in Geomatics World September/October 2016

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)